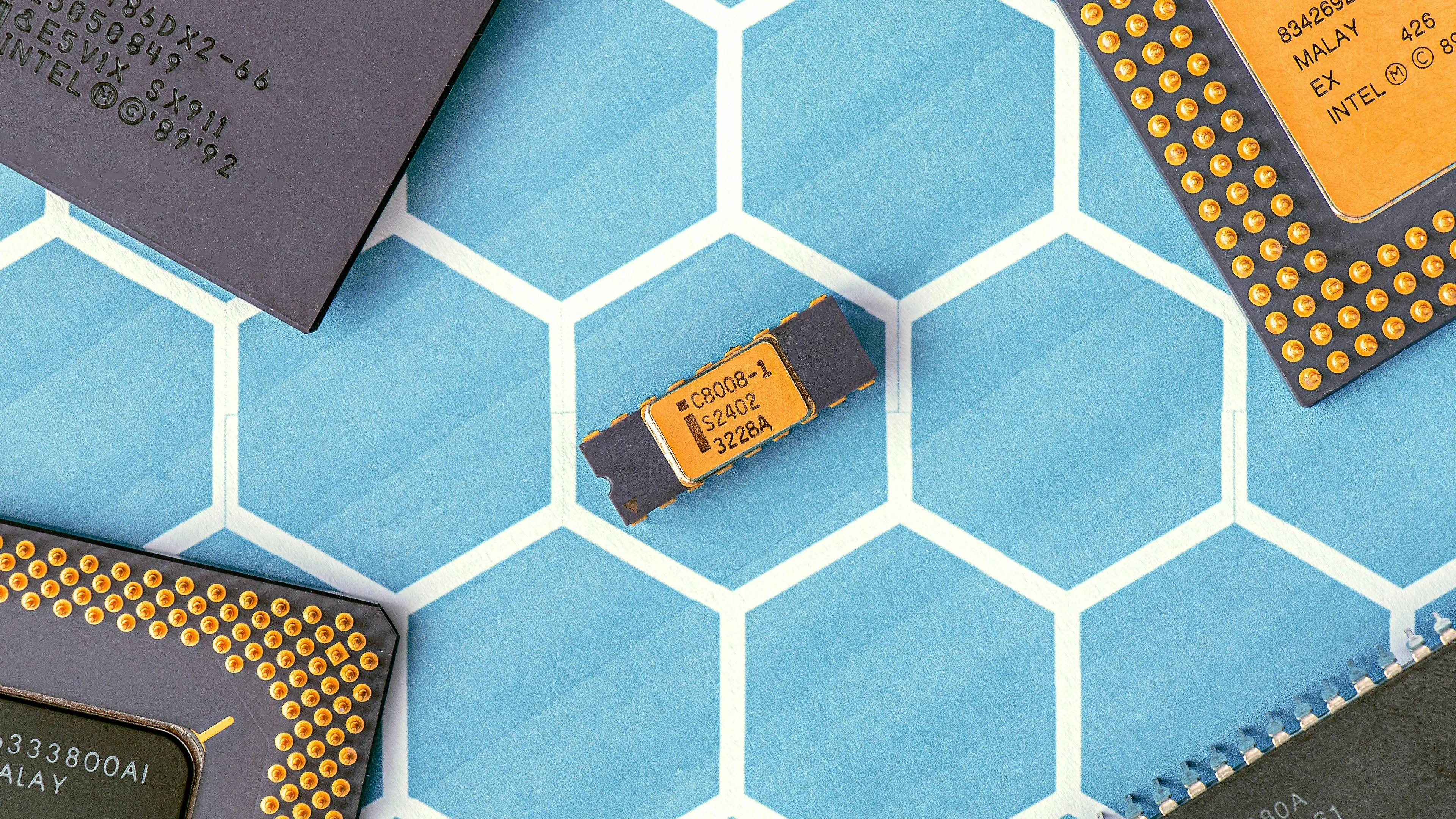

China’s Growing Need for Semiconductors

The past few years have been a semiconductor rollercoaster for China, but not the fun kind. Thanks to a barrage of trade restrictions from the West, China’s access to cutting-edge chips and chip-making equipment has been deliberately squeezed. We're talking about full-on export bans, tech embargoes, and the kind of bureaucracy that would make even seasoned procurement officers wince. The goal? Slow down China’s technological advancement, particularly in sensitive sectors like AI, 5G, and defense. And for a time, it worked. China’s tech sector took a hit, advanced fabs stalledm, and startups lost access to crucial EDA tools and lithography systems. Even legacy tech became harder to source reliably, and during this time, Western policymakers patted themselves on the back, assuming the problem was contained. But instead of waiting for sanctions to ease, China did what China does best, scale up, throw serious capital at the problem, and build parallel infrastructure. Thanks to this massive drive and desperation for cutting all Western dependencies, we now seeing the results of that effort: state-backed chip funds worth tens of billions, tech parks dedicated to semiconductor R&D, and a tidal wave of investment into local fabs and materials suppliers. This shift in tactic hasn’t just been about survival, it has also become a full-blown industrial strategy. While China may not be ready to produce bleeding-edge 2nm chips just yet, it’s getting dangerously close to being self-sufficient for the majority of its semiconductor needs, inclduing everything from IoT-grade microcontrollers to mid-range SoCs for AI inference and telecom infrastructure. So, what does this mean for the global chip landscape? It means that the West’s ability to control the flow of technology may have a shelf life. China's semiconductor capabilities are growing fast, much faster than anyone expected. Given the sheer scale and determination behind these efforts, there’s a real possibility that China may soon no longer need Western tech at all, at least for most of its domestic demand. Whether that's a cause for concern or admiration depends on your geopolitical lens. But from an engineering perspective, one thing is clear: cutting China off didn’t stop the race, it just made them build their own track.

Big Plans, Hollow Outcomes

China’s ambitious drive to build a world-class semiconductor industry has delivered some impressive technical milestones, from 7nm logic chips to competitive DRAM and 3D NAND. But beneath the headlines of success lies a less visible, costly underbelly: a sprawling graveyard of abandoned semiconductor factories, known as "zombie fabs," that have collectively burned through tens of billions of dollars.

According to a recent report by Toms Hardware, more than a dozen high-profile fabrication plant projects across China have collapsed over the past few years, despite a surge of investment tied to the country’s Made in China 2025 initiative. These failures, often the result of poor planning, lack of technical depth, fraud, and geopolitical headwinds, have left behind hollow factory shells scattered across provinces.

As of 2025, China has operated 44 wafer fabs, including 25 advanced 300-mm facilities, and at the same time, over 30 more fabs were under construction. Despite the many fabs going up, many of these ventures have never produced a single chip.

Among the most notorious is Wuhan’s Hongxin Semiconductor Manufacturing Co. (HSMC), a $19 billion project launched in 2017 to produce cutting-edge 14nm and 7nm chips. With no experience, no clear roadmap, and heavy dependence on government support, the company stalled amid land disputes and funding shortfalls. By 2021, the project was dead, with no wafers ever made.

Another particularly striking case is GlobalFoundries’ Chengdu fab, which had $1–$10 billion in planned investment. The site sat unused for five years after the company withdrew in 2018, until it was finally revived in 2023 by HLMC.

The failure of these ventures shows a serious flaw that is common among many of these Chinese semiconductor foundries: overreach. A number of startups attempted to leap directly into advanced nodes (such as 14nm or even 7nm), without R&D experience, skilled personnel, or secured access to critical equipment.

Making matters worse, U.S. export controls have barred Chinese firms from acquiring key chipmaking tools, especially for nodes below 10nm. These restrictions, first imposed in 2019 and expanded in subsequent years, have forced many ambitious projects into permanent limbo.

Current estimates suggest that failed fab ventures in China have cost investors (including state and local governments), between $50 billion and $100 billion. While a few projects, such as HLMC’s takeover of the GlobalFoundries site, hint at recovery potential, the vast majority remain stalled, abandoned, or mired in legal and financial disputes.

Even in less advanced segments like CMOS image sensors, projects like HiDM and Jiangsu Zhongjing Aerospace have failed, despite using simpler manufacturing nodes.

China’s experience highlights a hard truth about the semiconductor industry: money alone cannot buy technological leadership. Without deep technical ecosystems, robust supply chains, and long-term R&D, even well-funded national strategies can falter.

Among the most notorious is Wuhan’s Hongxin Semiconductor Manufacturing Co. (HSMC), a $19 billion project launched in 2017 to produce cutting-edge 14nm and 7nm chips. With no experience, no clear roadmap, and heavy dependence on government support, the company stalled amid land disputes and funding shortfalls. By 2021, the project was dead, with no wafers ever made.

Another particularly striking case is GlobalFoundries’ Chengdu fab, which had $1–$10 billion in planned investment. The site sat unused for five years after the company withdrew in 2018, until it was finally revived in 2023 by HLMC.

The failure of these ventures shows a serious flaw that is common among many of these Chinese semiconductor foundries: overreach. A number of startups attempted to leap directly into advanced nodes (such as 14nm or even 7nm), without R&D experience, skilled personnel, or secured access to critical equipment.

Making matters worse, U.S. export controls have barred Chinese firms from acquiring key chipmaking tools, especially for nodes below 10nm. These restrictions, first imposed in 2019 and expanded in subsequent years, have forced many ambitious projects into permanent limbo.

Current estimates suggest that failed fab ventures in China have cost investors (including state and local governments), between $50 billion and $100 billion. While a few projects, such as HLMC’s takeover of the GlobalFoundries site, hint at recovery potential, the vast majority remain stalled, abandoned, or mired in legal and financial disputes.

Even in less advanced segments like CMOS image sensors, projects like HiDM and Jiangsu Zhongjing Aerospace have failed, despite using simpler manufacturing nodes.

China’s experience highlights a hard truth about the semiconductor industry: money alone cannot buy technological leadership. Without deep technical ecosystems, robust supply chains, and long-term R&D, even well-funded national strategies can falter.

What Does This Mean for China’s Semiconductor Industry?

When it comes to centralized planning and industrial-scale spending, China doesn’t hold back. With its state-driven model, massive funding allocations are the norm, and so is the occasional (or frequent) misfire. Billions have been poured into semiconductor projects that either never launched or failed outright, but honestly, that shouldn’t shock anyone. In a top-down system, especially one focused on rapid results, money often ends up in the wrong hands or funnelled into the wrong phase of development. However, while foundries are certainly critical, they’re only one piece of the puzzle. You need talent including process engineers, materials scientists, IC designers, and fab managers, not just shiny cleanrooms and billion-dollar machines. Add to this the fact that fabs aren’t quick wins. They take years to build, longer to ramp, and even longer to become profitable. Unlike assembly lines or housing complexes, which China has mastered at scale, semiconductors demand long-term expertise, iteration, and deep ecosystem support. Despite all of this, China’s semiconductor trajectory may not be as compromised as it looks. Why would this be the case? Well, because China has already proven it can compete in key tech domains. Take RISC-V, where Chinese developers are leading some of the most advanced implementations, or NAND flash memory, a sector where domestic firms are holding their own.This clearly demonstrates that China isn’t just trying to copy, but trying to lead. So what about all those zombie fabs? Are they just sunk costs? For now, yes. But in a longer-term view, those facilities might still be valuable. Once the talent pool grows and supply chains stabilize, those empty fabs could become assets waiting to be reactivated, pre-built infrastructure for a more experienced generation of chipmakers. In the end, the real story isn’t about the wasted billions, but about the bigger trend: China is iterating. Fast. Mistakes were made, some big and some embarrassing, but the momentum is still forward. The semiconductor race is a marathon, not a sprint, and China’s proven it has the endurance. Will it dominate every segment? No. Will it catch up in the areas that matter most to its national strategy? That seems likely. Only time will tell, but if history is any guide, writing China off early has never been a great bet.