TDK has expanded its SensEI platform with the launch of edgeRX Vision, an ultra-fast defect detection system that combines high-precision optical inspection with AI-powered edge computing. Capable of detecting features as small as 1 mm by 0.5 mm, the system is designed to meet the needs of high-throughput manufacturing where speed, accuracy, and minimal downtime are essential.

TDK has expanded its SensEI platform with the launch of edgeRX Vision, an ultra-fast defect detection system that combines high-precision optical inspection with AI-powered edge computing. Capable of detecting features as small as 1 mm by 0.5 mm, the system is designed to meet the needs of high-throughput manufacturing where speed, accuracy, and minimal downtime are essential.

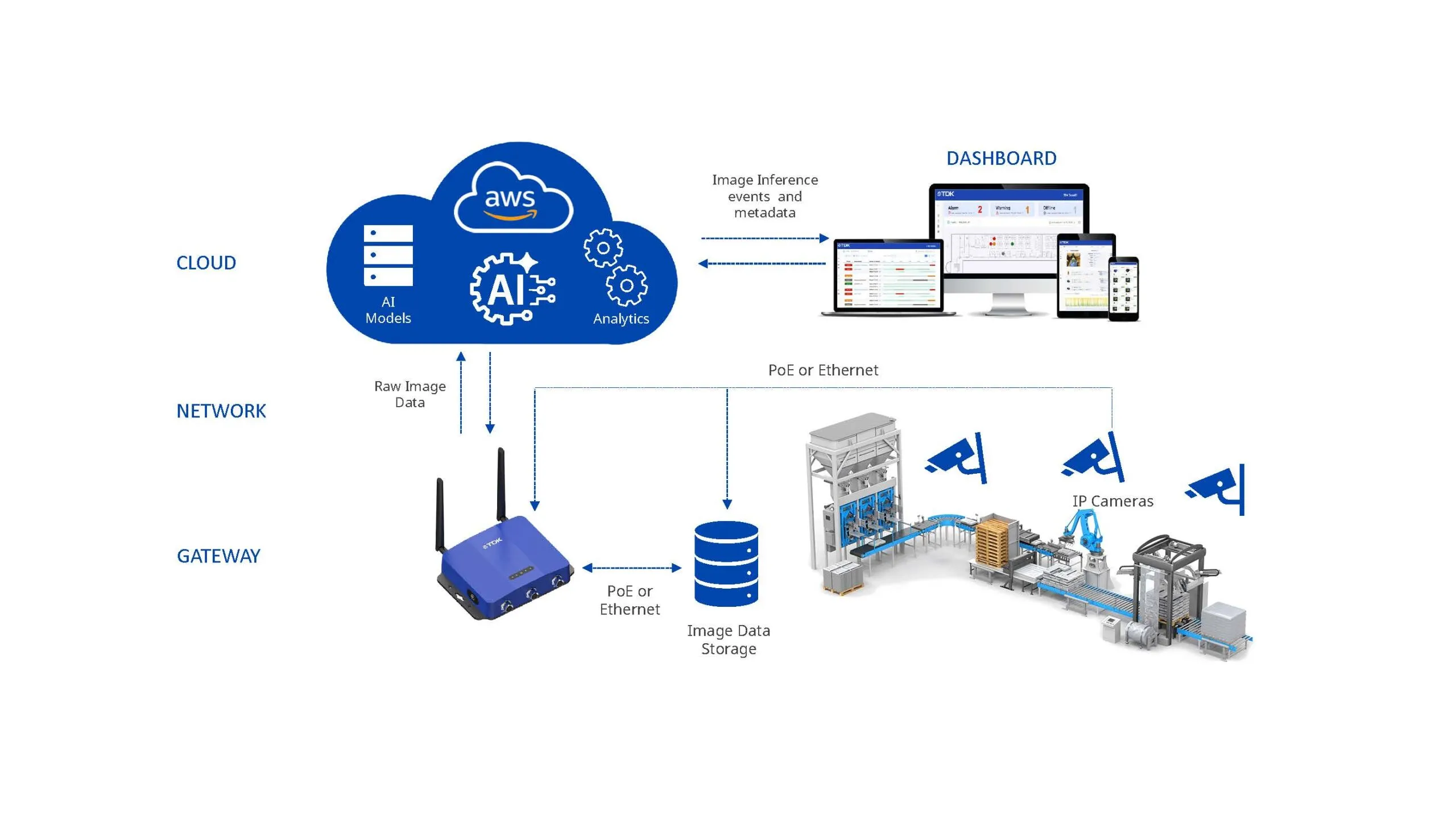

Operating at up to 2,000 parts per minute, edgeRX Vision uses AI to reduce false positives, improve product quality, and cut operational costs by eliminating unnecessary machine stoppages. It integrates seamlessly with TDK’s existing edgeRX sensors and hardware, enabling rapid deployment without major infrastructure changes.

According to Ken Takekawa, CEO of TDK Components USA, the solution targets small component inspection, like MLCCs (Multilayer Ceramic Capacitors), and leverages AI to lower the total cost of ownership. “By deploying AI on our existing hardware, we significantly reduced false positives, which means fewer interruptions and higher throughput,” said Takekawa. “At 2,000 parts per minute, those time savings really add up.”

Key Features

- Sub-millimetre defect detection

- Real-time analysis of images and video

- Adaptive AI models with continuous learning

- Reduced false positives and overkill

- Scalability across diverse product lines

The platform reflects broader advances in edge AI and computer vision. AI models can now process video data on-device with transformer-based architectures such as ViTs, or unified models like DINOv2 and Segment Anything Model (SAM). These models handle detection, segmentation, and classification tasks without retraining, and do so with less labelled data thanks to few-shot and self-supervised learning methods. The integration of multi-modal AI also enables better user interaction and system adaptability.

TDK SensEI CEO Sandeep Pandya added, “The launch of edgeRX Vision marks a major step forward in our mission to bring intelligent automation to the factory floor. It offers manufacturers a smarter, more integrated solution to modern production challenges.”

Applications

edgeRX Vision is designed for sectors where high-speed precision inspection is critical, including:

- Electronics manufacturing

- Pharmaceutical production

- Food and beverage quality control

Key Benefits

- Higher product quality with consistent defect detection

- Lower false rejection rates and reduced waste

- Greater production throughput with fewer delays

- Lower inspection costs through automation

As AI-driven inspection tools become more accessible and cost-effective, systems like edgeRX Vision are poised to play a central role in modernising production lines. For manufacturers looking to stay competitive, integrating AI at the edge is no longer optional; it’s an operational advantage.

Read the full press release here.