The Challenges of Modern Consumerism and E-Waste

Technology continues to accelerate at an unprecedented rate, and devices become obsolete faster than ever, where innovation cycles compress into months rather than years. On the surface, this appears beneficial: our lives are incrementally improved, communication becomes easier, and productivity tools grow more powerful. Furthermore, society adapts quickly, embracing the conveniences that these devices offer.

But these advancements carry a hidden cost; e-waste. The sheer volume of electronics produced today is mind blowing, and a growing fraction of it ends up discarded. Old smartphones, laptops, and other consumer electronics are rarely designed for longevity, with manufacturers favoring short product lifespans and rapid refresh cycles over re-usability and reliability. The result is devices that are difficult, if not impossible, to repair, with components that resist standard recycling processes.

Making matters worse, the environmental consequences of e-waste are severe. The improper disposal of electronics releases toxic materials into soil and water, creating risks that extend far beyond the original point of use. In many cases, e-waste is exported to countries with minimal regulatory oversight. While these regions may extract value from discarded hardware, the human and environmental toll far exceeds such benefits. Toxic exposure, unsafe working conditions, and contaminated land are common, leaving long-term problems that local communities must manage.

The current consumer-driven model treats electronics as disposable, ignoring the lifecycle costs of production, repair, and disposal. Engineers are pressured to optimize for sales rather than durability, and recycling systems lag behind the pace of innovation. Components that could be reused or repurposed are often lost in the process, further entrenching the cycle of waste. Until the industry reconciles rapid technological growth with responsible lifecycle management, e-waste will remain an unavoidable and growing problem.

Dissolvable 3D-Printed Electronics: A Step Toward Sustainable Hardware

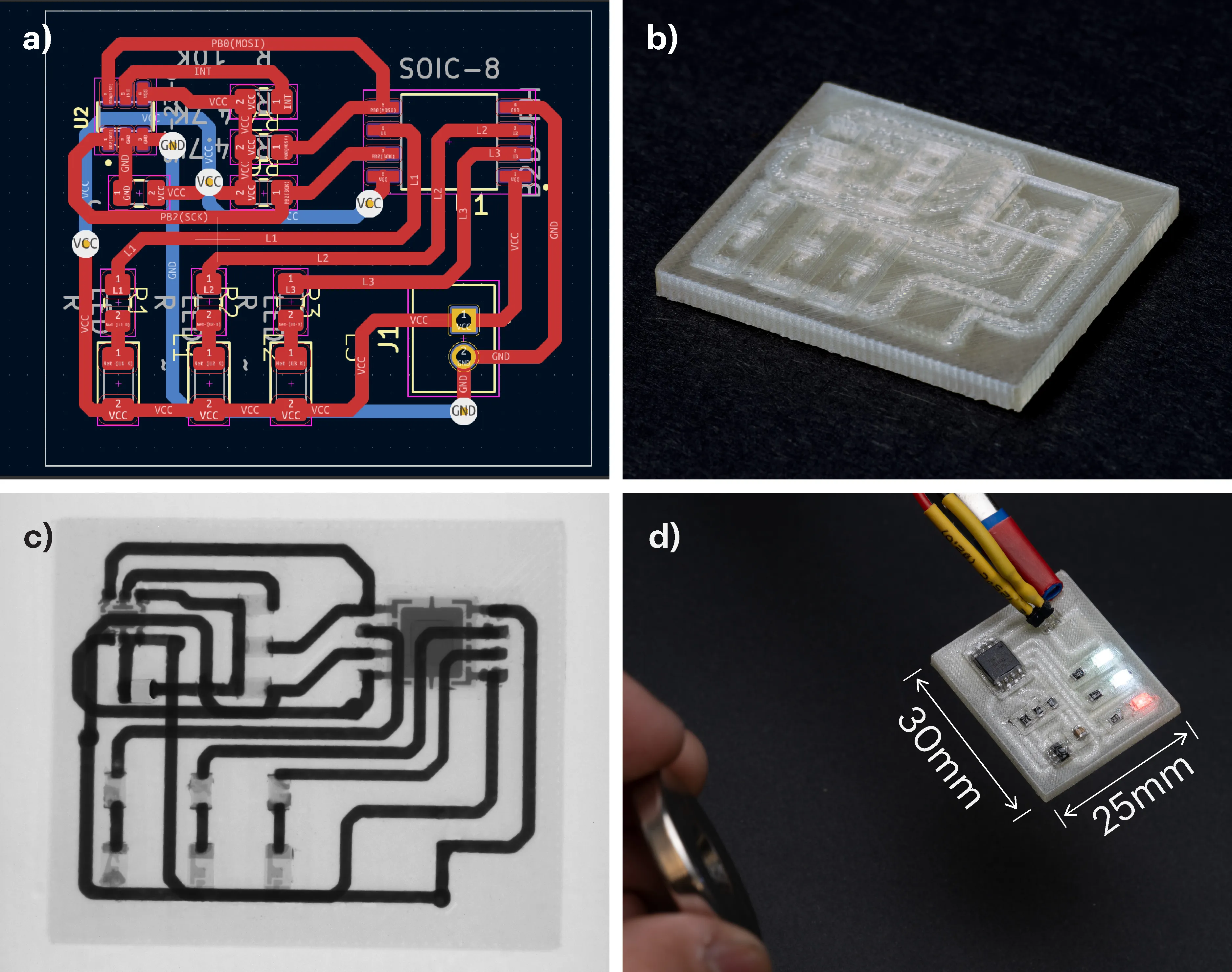

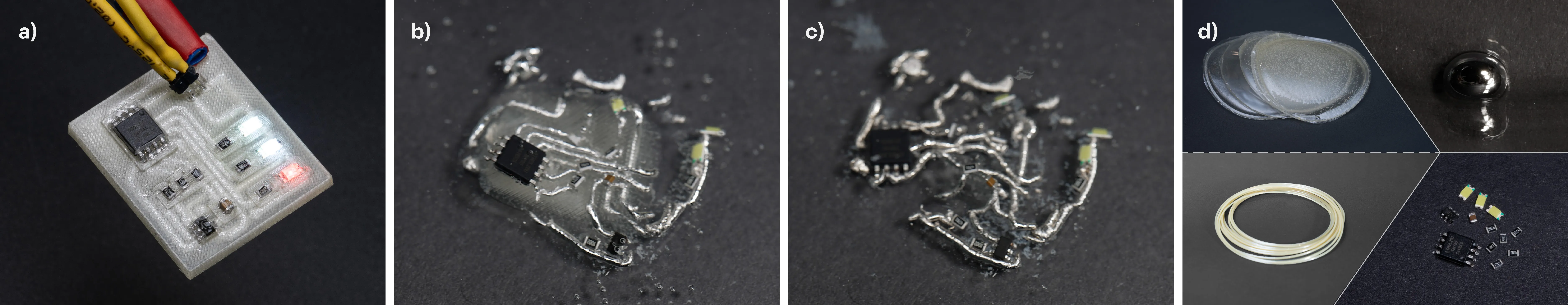

Recognizing the challenges presented by e-waste, researchers at the University of Maryland and the Georgia Institute of Technology have developed a fully functional circuit board that dissolves in water. The prototype, termed DissolvPCB, employs a polyvinyl alcohol (PVA) substrate (an inexpensive, water-soluble polymer), paired with liquid metal conductors made from eutectic gallium-indium (EGaIn). Off-the-shelf components are mounted conventionally, and once the device reaches end-of-life, the board can be immersed in water to enable recovery and reuse of nearly all materials.

The motivation for creating a dissolvable PCB comes from the extreme difficulty in recycling FR4, the most common PCB substrate. FR4 composites require energy-intensive processes that generate harmful byproducts, making recovery of these materials both costly and inefficient. It is this fact taht sees the overwhelming majority of discarded electronics not being recycled.

The DissolvPCB concept, however, directly addresses recyclability by integrating it into the design stage. The early test results of the newly developed substrate are promising: recovery yields exceeded 98% for metals and 99% for substrate material, with electronic components remaining functional after reclamation. The process is also low-cost and does not depend on specialized infrastructure, making local recovery feasible.

Could Dissolvable PCBs Solve the E-Waste Problem?

The concept of dissolvable PCBs is technically impressive and environmentally attractive. By designing circuit boards that can be broken down into reusable materials, researchers have demonstrated a direct method of addressing one of the most stubborn contributors to e-waste. The ability to recover substrates, conductors, and components without industrial-scale processing offers a potential route to localized, low-cost recycling. If developed further, such systems could reduce the volume of toxic materials entering landfills and limit the export of hazardous waste to poorly regulated regions.

Equally important is the opportunity for component reuse, as conventional recycling often destroys valuable parts in the process. This process, however, could allow integrated circuits, passives, and connectors to be harvested intact. This represents a more efficient use of resources and extends the useful life of individual components.

However, the technology is not without major constraints. To start, current prototypes are limited in complexity and durability, and they cannot compete with the thermal stability and mechanical reliability of FR-4 boards used in critical sectors such as automotive, aerospace, or industrial control. Dissolvable substrates may also find applications in short-lived consumer products or prototyping, but are unlikely to replace conventional boards in safety-critical systems in the near term.

Overall, dissolvable PCBs are a promising step toward addressing the e-waste challenge, but they are not a universal solution. Their greatest impact may be in shifting design priorities: showing that recyclability can be engineered into hardware, rather than treated as an afterthought. Whether this approach matures into an industry standard remains uncertain, but it has opened an important conversation about the role of materials science in sustainable electronics.