As vehicles take on more electric systems and smarter control units, the strain on wiring and connectors has quietly increased. Engineers working on modern ECUs now deal with thicker power lines, higher sustained currents and a mix of modules that all expect reliable delivery without the bulk of older connector families. JAE’s MX81D Series sits in that space. It brings a 2.8 mm terminal format and enough headroom for high power automotive subsystems, but it does so without forcing changes to harness tooling or module layout.

As vehicles take on more electric systems and smarter control units, the strain on wiring and connectors has quietly increased. Engineers working on modern ECUs now deal with thicker power lines, higher sustained currents and a mix of modules that all expect reliable delivery without the bulk of older connector families. JAE’s MX81D Series sits in that space. It brings a 2.8 mm terminal format and enough headroom for high power automotive subsystems, but it does so without forcing changes to harness tooling or module layout.

Evolving Power Needs Inside the Vehicle

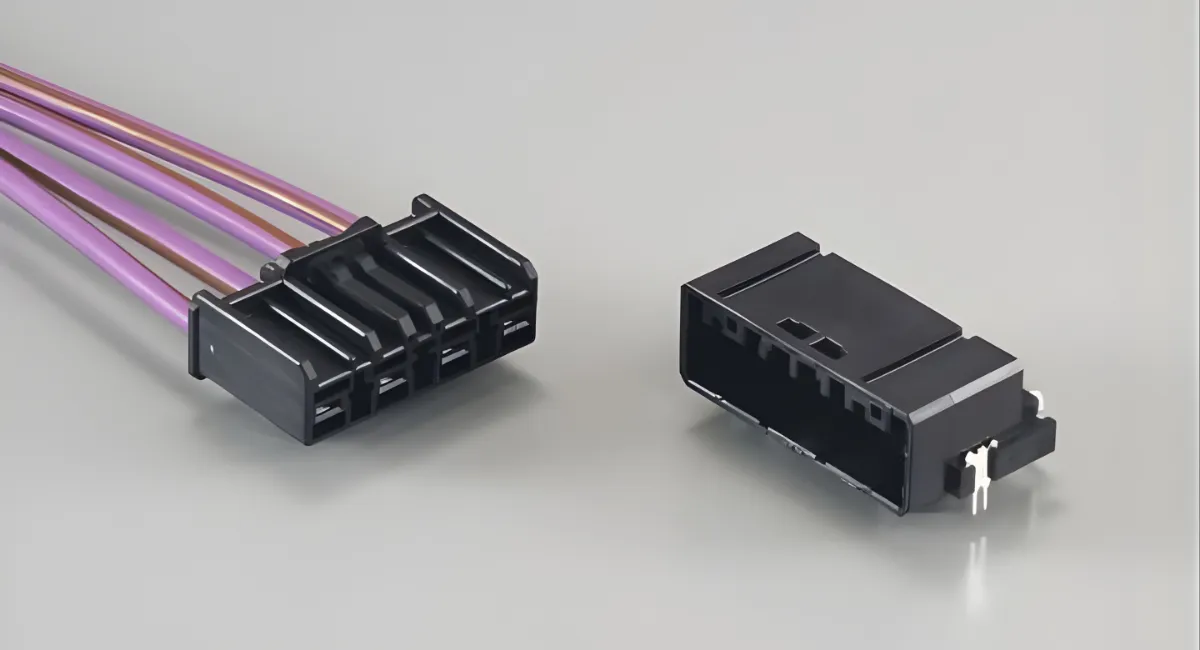

Automotive engineers have watched current requirements creep upwards as power steering units, heater blowers and larger infotainment systems draw more energy across the loom. Older 0.64 mm terminals reach their limit quickly in these scenarios. The MX81D shifts to a 2.8 mm tab, opening up support for wires from 1.5 to 4.0 mm² and allowing up to 25 A on the largest gauge. That step may seem simple, but it helps keep module footprints familiar while giving ECUs the current margin they need.

Electrical Behaviour and Standards That Matter

The MX81D is built to hold up in the kind of environments ECUs now face. Compliance with IEC 60664-1 ensures insulation distances remain correct even in polluted or high-altitude operation around 6000 m. The connector also meets USCAR-2 and USCAR-21, which remain the practical benchmarks for vibration, mechanical endurance and long-term contact reliability in vehicles. Housing plastics rated UL94 V-0 add fire resistance that many enclosed modules depend on. The result is a connector that feels designed for real vehicle conditions rather than idealised ones.

Design Choices That Support Production

One feature likely to stand out for harness engineers is the preset retainer inside the socket housing. It detects partial terminal insertion, a problem that still appears more often than most teams would admit. By catching mis-seated contacts before final assembly, the connector reduces rework and fits more smoothly into automated harness lines. The four-position layout covers common ECU formats, and the minus 40 to plus 125 degree range means it can sit in both interior modules and protected under-dash locations.

Where It Fits in Vehicle Architectures

JAE positions the MX81D for a wide set of ECU roles: power steering, heaters, audio equipment, battery management, motor drive modules, overhead electronics and even some ADAS boxes. The connector uses a tab size already recognised across ISO, JASO, EWCAP and VDA, so integration stays straightforward. JAE has also hinted at hybrid versions mixing 0.64 mm and 2.8 mm terminals, which could simplify harness routes by combining signal and power in one housing.

How This Influences Future Designs

As vehicles take on more electronics, power connectors must evolve without forcing a rewrite of established harness architecture. The MX81D Series is a good example of that incremental evolution. It increases power capability, improves assembly robustness and keeps compatibility with existing manufacturing processes. For engineers balancing performance with packaging and production constraints, this kind of connector is becoming essential rather than optional.

Learn more and read the original announcement at www.jae.com