High voltage motor drives and power conversion stages place a tough set of constraints on the interface between logic and switching devices. Gate drivers sit in the middle of that problem, where noise, switching speed and device protection all shape system behaviour. Microchip’s new 600V gate driver family is aimed at this space, giving engineers a set of devices that maintain reliable control across demanding industrial and consumer power designs.

High voltage motor drives and power conversion stages place a tough set of constraints on the interface between logic and switching devices. Gate drivers sit in the middle of that problem, where noise, switching speed and device protection all shape system behaviour. Microchip’s new 600V gate driver family is aimed at this space, giving engineers a set of devices that maintain reliable control across demanding industrial and consumer power designs.

Designed for High Voltage Switching Environments

Motor control and offline power conversion place gate drivers in conditions where dv dt spikes and ground shifts can distort signals. The new 600V family includes half bridge, high side and low side, and three phase options, which allows designers to align the driver topology with the power stage architecture rather than adapting the system around a fixed device. Each driver supports fast switching and current drive ratings from 600mA to 4.5A, which is useful when working across different MOSFET or IGBT sizes.

The inclusion of 3.3V logic compatibility makes these parts straightforward to pair with modern MCUs without extra level shifting. In practice this removes a small but common source of timing uncertainty in designs that have to synchronise high frequency switching with digital control loops.

Behaviour Tuned for Noisy Power Stages

High voltage systems tend to be noisy in ways that directly influence gate drive reliability. Schmitt triggered inputs help define clean switching thresholds, while the enhanced noise immunity reduces false triggering when switching edges propagate through the layout. Internal deadtime is included to prevent shoot through, which is particularly useful when working with engineers who prefer integrated timing protection over external logic.

This behaviour helps stabilize designs where switching frequency, layout constraints or package parasitics make it difficult to maintain predictable turn on and turn off intervals.

Integration With Microchip Control and Power Devices

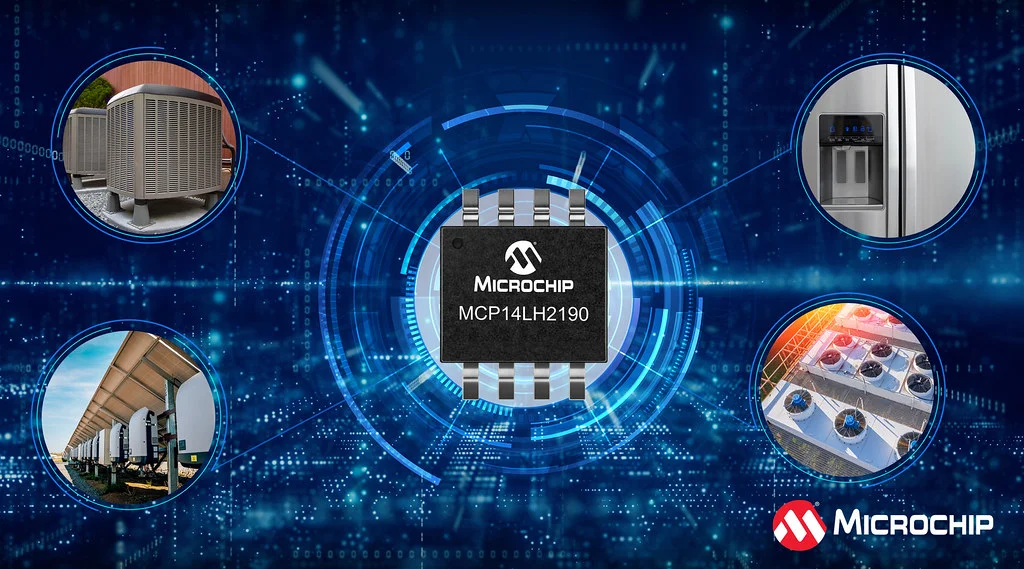

Microchip positions this family to sit alongside its MOSFETs and MCUs, which creates a consistent set of building blocks for industrial and consumer motor drives. In real applications this can streamline firmware development, timing coordination and the modelling of switching behaviour. The drivers align with industry trends toward higher efficiency, smaller inverter footprints and the movement of industrial systems toward greater electrification.

In renewable energy systems and motor based consumer products, these devices support the shift toward compact power stages that operate at higher voltages without adding unnecessary design overhead.

Practical Considerations for Prototyping and System Development

Before hardware is built, simulation models are available to evaluate driver behaviour at different switching frequencies and load conditions. This can help identify deadtime margins, bootstrap behaviour and MOSFET gate charge interactions early in the design cycle. Once in production, the availability of multiple package and topology options gives teams flexibility to reuse a common driver family across several platforms. For engineers building DC DC supplies, inverters or multi phase motor controllers, this portfolio offers a set of drivers that prioritise predictable switching and noise tolerant operation rather than relying on external protection circuitry.

Learn more and read the original announcement at www.microchip.com