The Challenge of Wearable Electronics

Wearable devices have long been a focus of electronics research, yet they remain largely niche rather than mainstream. While smartwatches have gained some traction, more ambitious wearables such as augmented reality glasses or full-body sensor arrays have struggled to achieve sustained adoption.

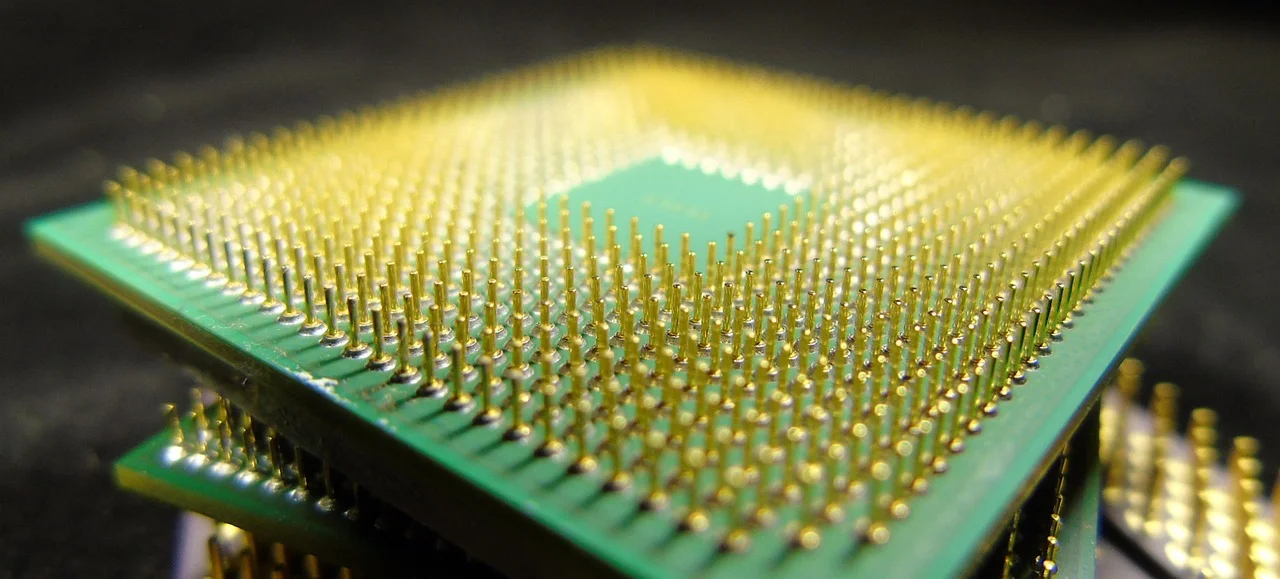

The underlying technical limitation is fundamental: conventional electronics are rigid. Standard silicon dies, discrete components, and soldered interconnects resist bending and flexing. When these rigid structures are forced to conform to a human body’s natural movement, mechanical stresses concentrate at solder joints and lead frames, causing microfractures and eventual device failure.

Flexible printed circuit boards offer partial mitigation, providing some compliance in the interconnect substrate itself. However, components themselves, including transistors, passive elements, and memory, remain inherently rigid. Even if the board substrate can bend, repeated flexing introduces strain on the component pins, often resulting in intermittent connections or outright fractures over relatively short periods of use.

Attempts to address this through printed electronics, specialized conductive filaments, or stretchable interconnects have demonstrated laboratory feasibility, but these approaches struggle to deliver the density, performance, and reliability required for commercial wearable devices. High-performance processing, complex sensors, and memory integration are difficult to maintain when the device substrate itself is deformable. The result is that until recently, truly autonomous, flexible wearables have remained constrained by physics as much as by materials.

Flexible AI Chips Bring Computation to Wearables

A recent development from researchers at Tsinghua University and Peking University has addressed these limitations by fabricating a flexible AI chip, known as FLEXI, directly on a compliant substrate. The device uses low-temperature polycrystalline silicon (LTPS) on a plastic base, enabling bending, twisting, and folding without damaging the circuitry.

By reducing the thermal budget during fabrication, the researchers preserved the integrity of the plastic substrate while maintaining transistor performance. FLEXI’s die thickness is on the order of a human hair, and durability testing shows it can withstand over 40,000 bending cycles and fold to a one-millimeter radius with negligible degradation. Unlike conventional wearables, which rely heavily on cloud servers or paired smartphones for computation, FLEXI processes AI workloads locally. Local processing reduces latency, avoids continuous high-bandwidth wireless communication, and dramatically cuts energy consumption. Bench testing demonstrated 99.2% accuracy in detecting arrhythmias and 97.4% in activity classification while consuming less than 1% of the energy typical of conventional rigid AI chips.

Potential applications extend across autonomous health monitors, smart textiles, voice-processing earbuds, and untethered AR glasses. The researchers plan to integrate additional sensors and capabilities while preserving mechanical compliance, illustrating a pathway toward edge intelligence that does not rely on external devices.

Is this another fad, or the real thing?

While FLEXI’s achievements are technically impressive, the device remains a laboratory prototype. Operating at 12 MHz with 2.5 mW power consumption, it is capable of simple AI tasks but falls short of the computational throughput demanded by many real-world applications. Modern wearables require parallel processing, high-resolution sensing, and low-latency inference for complex tasks, placing stringent requirements on memory bandwidth, interconnect density, and system-level energy efficiency. FLEXI demonstrates that flexible processing is possible, but scaling this to fully autonomous, multi-sensor wearables remains a substantial engineering challenge.

The value of this research lies not in immediate commercialization but in the techniques and materials it validates. LTPS on flexible substrates, combined with mechanical design that accommodates extreme bending, establishes a foundation for more advanced devices. The work suggests that high-performance computation in wearables does not have to be constrained by rigid substrates or cloud dependence. Over the next decade, these approaches could redefine what constitutes feasible wearable electronics, enabling devices that are mechanically robust, energy efficient, and computationally capable, while remaining comfortable and unobtrusive for the wearer.