High-current rectifiers tend to get overlooked in modern power conversations. Everyone talks about SiC, fast recovery, synchronous stages. Yet in many industrial systems, the diode is not chasing switching speed. It is absorbing line rectification stress, surge events, and repeated thermal cycling without drifting out of spec. That is where parts like Diotec’s PW4512 sit. Not flashy. Just 1200V class silicon handling real current in environments that are rarely gentle.

High-current rectifiers tend to get overlooked in modern power conversations. Everyone talks about SiC, fast recovery, synchronous stages. Yet in many industrial systems, the diode is not chasing switching speed. It is absorbing line rectification stress, surge events, and repeated thermal cycling without drifting out of spec. That is where parts like Diotec’s PW4512 sit. Not flashy. Just 1200V class silicon handling real current in environments that are rarely gentle.

Standard Recovery Where Speed Is Not The Priority

The PW4512 is a standard recovery diode with a reverse recovery time in the microsecond range, roughly 1500ns. That immediately tells you what it is not meant for. It is not intended for high-frequency boost PFC at tens of kilohertz where recovery charge dominates switching loss. Instead, it fits lower-frequency rectification and freewheel roles where conduction robustness matters more than nanosecond behavior.

At 45A average forward current, forward voltage stays under about 1.1V at room temperature. In real assemblies that number does not stay at 25°C for long. Junction temperature rises. Heatsinks warm up. Even so, shaving tens of millivolts at high current still translates to several watts of difference once the system settles thermally. That matters in sealed industrial enclosures where airflow is not guaranteed.

Surge Events And Line-Frequency Reality

Large input capacitors do not charge politely. When a supply first energizes, surge currents spike briefly and then disappear, but components remember. The PW4512 tolerates non-repetitive surge currents in the region of 300A for a 10ms pulse. In practice, that margin protects against those initial inrush events and occasional line disturbances. You do not see this in a clean schematic. You see it when a field unit trips repeatedly after a brownout and someone traces the issue back to a marginal rectifier. Surge capability is not about peak numbers. It is about avoiding slow degradation over years of service.

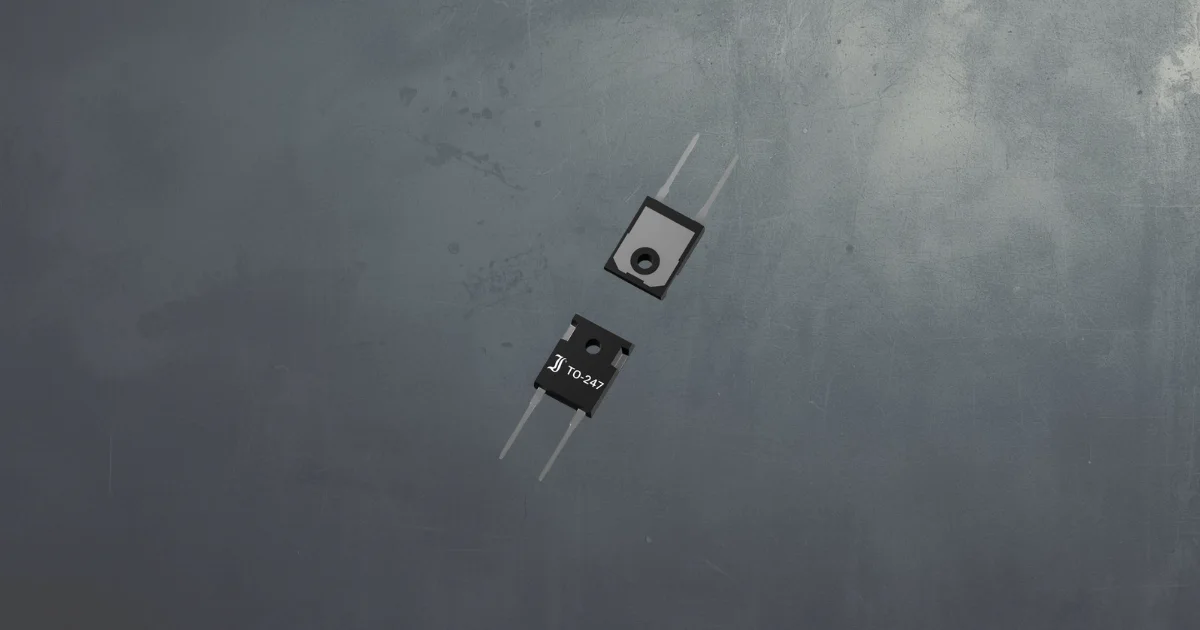

TO-247 Thermal Path And Mechanical Familiarity

The device is housed in a TO-247-2L package, a form factor that remains common in inverter legs and industrial front ends. Mounting to a heatsink is straightforward. There is no exotic clamping hardware or integrated module baseplate to accommodate. For designers who have laid out motor drives or UPS input stages before, the mechanical story is already familiar.

At 1200V repetitive reverse voltage, the diode provides margin for rectified three-phase inputs or higher-voltage DC rails derived from battery stacks. Clearance and creepage on the PCB still require attention, of course. But the silicon itself is comfortable at that blocking level.

Where Standard Recovery Still Makes Sense

Not every application benefits from ultrafast recovery or wide bandgap materials. In polarity protection, OR-ing, battery charging, or line-frequency rectification, predictable behavior and rugged surge tolerance often outweigh switching finesse. The PW4512 aligns with those segments. There is a tendency to assume that newer automatically means better. Sometimes the requirement is simply a high-voltage, high-current rectifier that survives real-world abuse without complaint. In industrial power, that is not a small requirement.

Learn more and read the original announcement at www.diotec.com