At 224G PAM-4, the board is no longer neutral territory. Every millimeter of copper between the ASIC and the outside world adds loss you cannot afford, and equalization budgets start to look uncomfortable. Designers can push materials, tweak stackups, shorten routes, but eventually the trace itself becomes the problem. Molex’s Impress Co-Packaged Copper solution responds by moving the connection point off the PCB and directly onto the ASIC package substrate, which quietly changes the geometry of the entire channel.

At 224G PAM-4, the board is no longer neutral territory. Every millimeter of copper between the ASIC and the outside world adds loss you cannot afford, and equalization budgets start to look uncomfortable. Designers can push materials, tweak stackups, shorten routes, but eventually the trace itself becomes the problem. Molex’s Impress Co-Packaged Copper solution responds by moving the connection point off the PCB and directly onto the ASIC package substrate, which quietly changes the geometry of the entire channel.

Shrinking the Electrical Path to the Package Edge

Traditional high-speed architectures route signals from the ASIC, through the package, across the PCB, and into a connector that then hands off to a cable or another board. At 56G this was manageable. At 112G it required discipline. At 224G PAM-4, the channel margin starts disappearing long before the signal reaches the edge of the board.

Impress shifts that boundary inward. The compression-based connector is attached directly to the ASIC substrate, reducing how much of the high-speed path lives inside the PCB laminate. Less distance in FR-4 means less insertion loss, less crosstalk exposure, and a different equalization burden at the SerDes. The full channel is treated as an integrated path from die to cable, rather than as a board problem followed by a connector problem. That distinction matters once you are operating near the limits of copper.

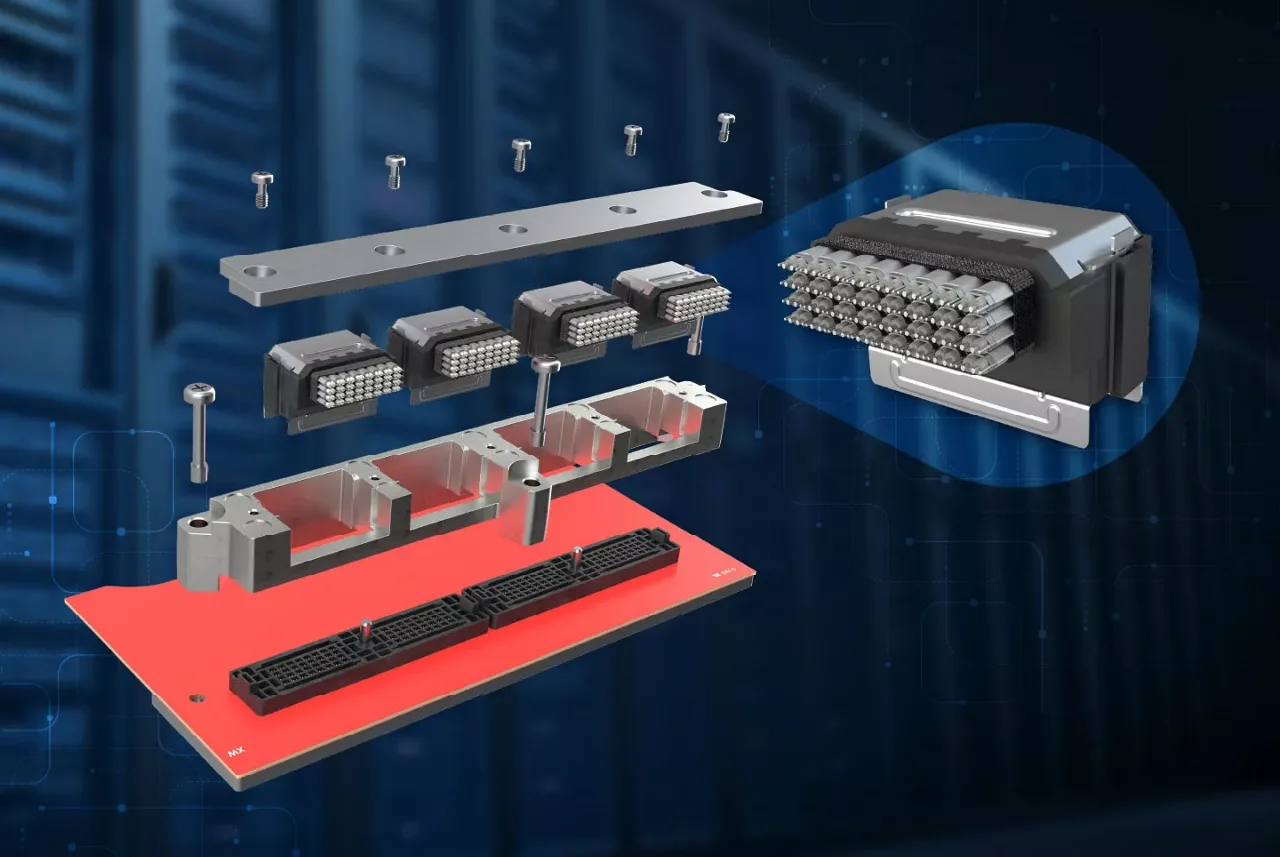

Compression Attachment and Substrate Protection

Attaching anything to an ASIC substrate is not trivial. It is a delicate and expensive layer, and rework is not something designers take lightly. Impress uses a compression-based socket interface rather than a permanent soldered joint, which changes the maintenance equation. Because the socket is compression-attached to the substrate, the mechanical stress profile is different from conventional high-speed connectors that rely on rigid solder interfaces. This allows removal and replacement without directly reflowing the substrate itself. In dense AI accelerator trays where downtime carries real cost, that difference is not abstract. You feel it the first time a module needs service without scrapping the package.

The mating cable assembly incorporates over-molded strain relief and mechanical contact wipe features to preserve long-term durability, which becomes relevant when systems are deployed in high-density racks subject to repeated service cycles. At these speeds, reliability is not just about bit error rate. It is also about mechanical consistency over time.

Navigating the 224G Inflection Point

The move from 1.6T to 3.2T networking and the broader 224G ecosystem is less about headline bandwidth and more about architectural compression. Switch silicon continues to scale lane rates, but board real estate does not scale at the same pace. Thermal envelopes are tighter. Power delivery paths compete with signal breakout.

By placing the connection directly on the ASIC package, Impress reduces the burden on the PCB and opens different layout tradeoffs. Power distribution and high-speed routing no longer fight for the same surface area in quite the same way. It is not that copper suddenly becomes lossless. It is that the loss is managed closer to the silicon, where the channel can be more tightly controlled.

Development work is already underway to validate the approach for 336G and 448G environments, which suggests the substrate-level strategy is not a temporary workaround but a directional shift. Once trace length becomes the limiting factor, moving the connector boundary inward is a logical next step, even if it forces designers to rethink what “board-level interconnect” really means.

Learn more and read the original announcement at www.molex.com