As factory systems grow smarter and more connected, the pressure on hardware designers is mounting. Control cabinets are getting smaller. Data loads are increasing. Maintenance windows are shrinking. These shifts aren’t just cosmetic. They demand connectors that work harder, fit tighter, and fail less. In response, HARTING has introduced three new solutions designed to help engineers build more reliable and efficient systems: the Han Protect connector, a PushPull variant of the D-Sub interface, and a Single Pair Ethernet (SPE) solution already being tested by North American rail operators.

As factory systems grow smarter and more connected, the pressure on hardware designers is mounting. Control cabinets are getting smaller. Data loads are increasing. Maintenance windows are shrinking. These shifts aren’t just cosmetic. They demand connectors that work harder, fit tighter, and fail less. In response, HARTING has introduced three new solutions designed to help engineers build more reliable and efficient systems: the Han Protect connector, a PushPull variant of the D-Sub interface, and a Single Pair Ethernet (SPE) solution already being tested by North American rail operators.

Each product targets a different but overlapping need: reduced panel space, tool-free access, or lighter network infrastructure. What ties them together is a focus on maintainability, performance, and physical simplicity, factors often overlooked until they become a problem.

Han Protect Brings Fuses Outside the Cabinet

Traditional fuse replacement means downtime. Someone qualified needs to open the cabinet, identify the fault, and replace the part. This isn’t always fast, and it’s rarely safe. Han Protect changes that by embedding the fuse holder into the connector housing and moving it outside the enclosure entirely. From the front panel, technicians can swap a fuse in seconds without special training or tools. There’s even an LED on the housing that shows whether the fuse has blown, eliminating the need to probe or test.

The internal benefits are just as important. With the fuse block gone, designers can free up significant space inside the cabinet, up to 30 percent in some layouts. That space can be used for additional I/O, smaller enclosure footprints, or simply better airflow. In dense automation systems, every centimetre matters.

The internal benefits are just as important. With the fuse block gone, designers can free up significant space inside the cabinet, up to 30 percent in some layouts. That space can be used for additional I/O, smaller enclosure footprints, or simply better airflow. In dense automation systems, every centimetre matters.

D-Sub PushPull Connects Fast, Releases Cleanly

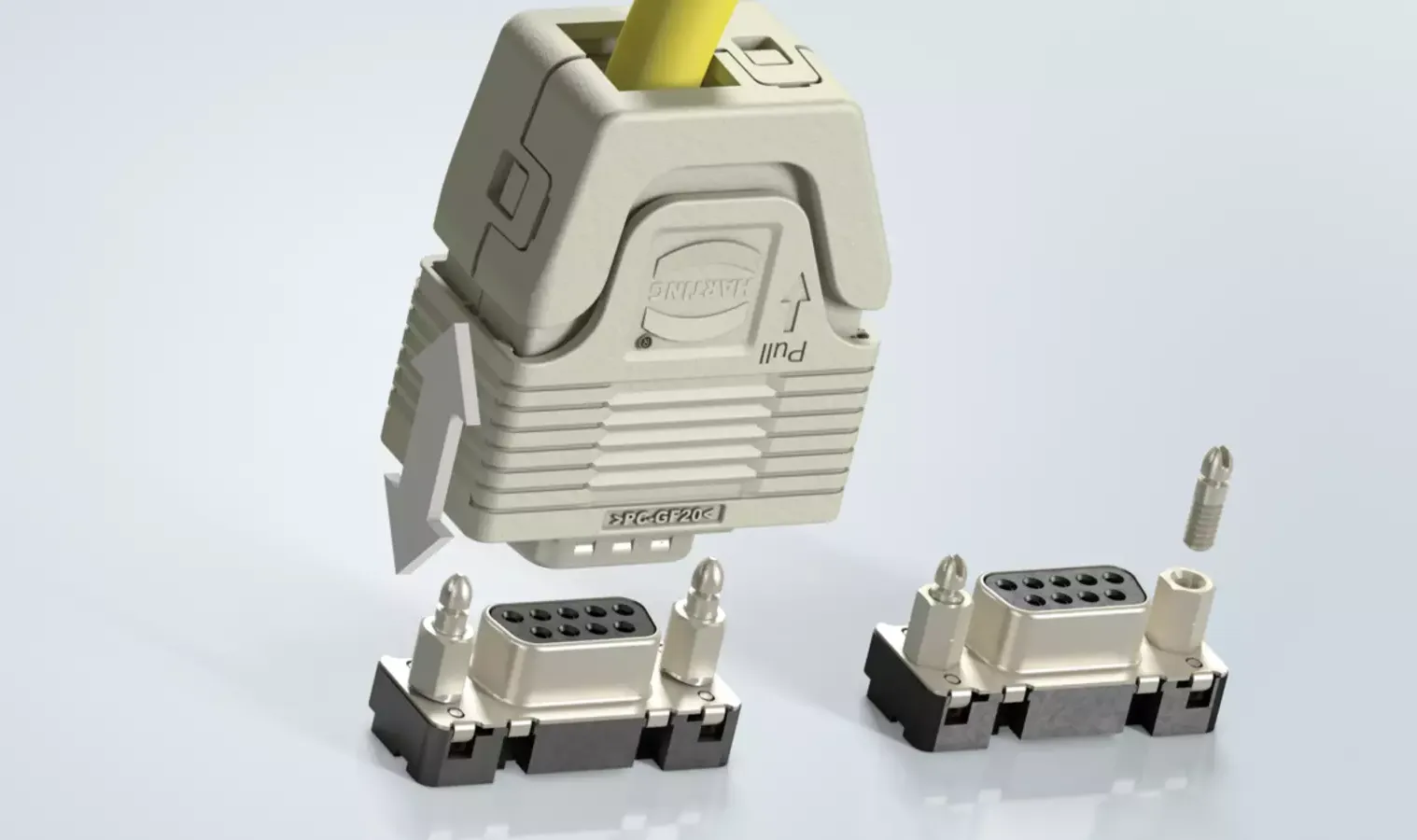

The D-Sub interface has been a workhorse of industrial systems for decades, but it was never designed for tight, tool-free applications. HARTING’s new PushPull version reimagines the familiar connector with a locking system that clicks into place and releases from any angle. Installers no longer need to get a spanner inside the rack, and disconnection is a simple pull rather than a frustrating twist.

Despite the upgrade, the connector remains fully backward-compatible with standard D-Sub footprints. That means existing systems don’t need to be redesigned, and spare parts inventories can remain lean. It’s a rare case where installation time is reduced without introducing friction elsewhere in the process.

Mechanically, the housing is rugged enough for high-vibration environments and resists the kinds of wear that normally plague rapid-connect systems. Whether it’s a test stand, robot arm, or mobile equipment rack, the PushPull holds its own.

Mechanically, the housing is rugged enough for high-vibration environments and resists the kinds of wear that normally plague rapid-connect systems. Whether it’s a test stand, robot arm, or mobile equipment rack, the PushPull holds its own.

Single Pair Ethernet Brings Rail-Tested Simplicity

HARTING’s SPE technology has already passed one of the hardest tests available: locomotive-to-locomotive communication. In freight applications, cable runs are long, space is tight, and every kilogram matters. Moving from a four-pair Ethernet cable to a single pair cuts weight by half and simplifies routing through bulkheads or along cramped chassis channels.

Performance is equally compelling. The system supports 10 Mbps over 1000 metres of cable, enough for most automation, control, and diagnostics workloads. And it’s forward-compatible. Future variants are expected to handle 1 Gbps and beyond, giving designers a clear upgrade path without changing the cabling infrastructure.

In industrial applications, the benefits are just as clear. SPE simplifies installations, reduces copper usage, and opens up Ethernet connectivity for edge devices in ways traditional cabling cannot match. For sensor networks, mobile equipment, or modular factory layouts, it’s a significant shift.

In industrial applications, the benefits are just as clear. SPE simplifies installations, reduces copper usage, and opens up Ethernet connectivity for edge devices in ways traditional cabling cannot match. For sensor networks, mobile equipment, or modular factory layouts, it’s a significant shift.

Designed to Work Regionally, Not Just Globally

While these products are engineered for global applications, HARTING has built them with regional realities in mind. The company’s North American teams are responsible for design input, production, and support, ensuring that local compliance, lead times, and logistics are addressed from the start. This local-first model aligns well with today’s need for faster deployment and greater supply chain control.

Smart factories don’t happen in isolation. They rely on simple, reliable parts doing exactly what’s expected of them. With the Han Protect, D-Sub PushPull, and SPE solutions, HARTING isn’t chasing trends, it’s reinforcing the foundation.

Learn more here.