Battery systems are running hotter than ever as EV makers push for faster charging and more power-dense packs. Spotting local hot spots early can prevent tripped protection circuits or, in the worst case, battery damage.

Battery systems are running hotter than ever as EV makers push for faster charging and more power-dense packs. Spotting local hot spots early can prevent tripped protection circuits or, in the worst case, battery damage.

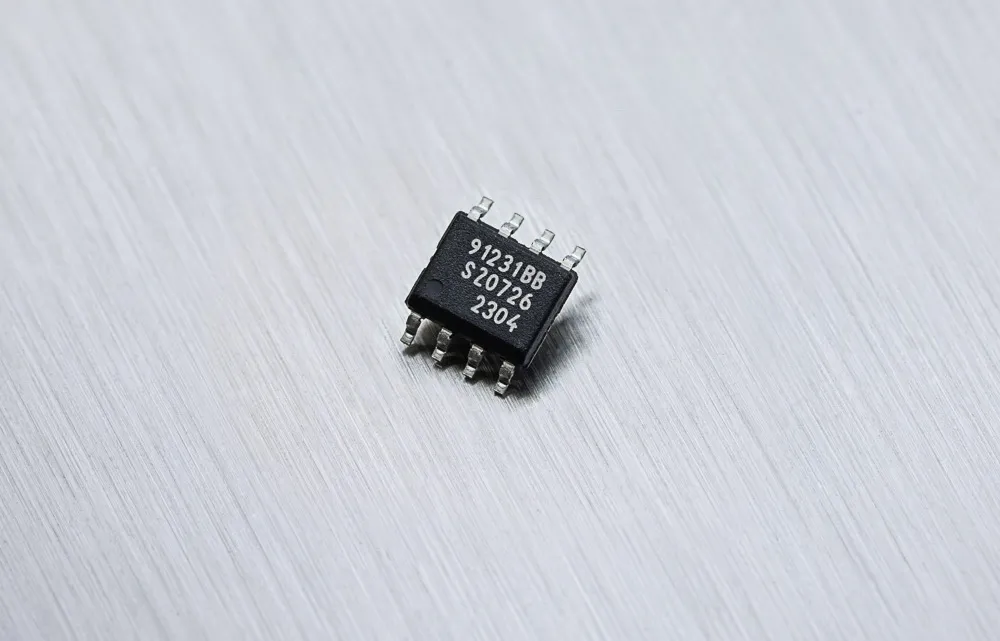

Melexis has refreshed its MLX91230 Hall-based sensor and MLX91231 shunt-based IVT device with a new external NTC input. Instead of just measuring its own junction temperature, the IC can now monitor a shunt or nearby busbar, giving engineers a much clearer picture of what’s happening thermally. In practice this means better detection of temperature gradients, quicker fault response, and more accurate current readings thanks to shunt drift compensation.

Safety-Critical by Design

The added input is ASIL C compliant, which makes it ready for use in battery disconnect units, pyro-fuse circuits, and other high-integrity parts of the BMS. Built-in overcurrent detection can even trigger a pyro-fuse directly, so there’s no need for extra analog components. This can save space, cut cost, and make it easier to pass ISO 26262 safety assessments.

Simplified System Architecture

With current, voltage, internal temperature, and now external temperature handled in one chip, there’s less wiring and fewer devices to manage. The integrated microcontroller and flash memory give teams room to run their own calibration or protection routines, while LIN, UART, and UART-over-CAN interfaces cover everything from simple local nodes to distributed packs several metres long.

Beyond Automotive

Although designed with 12 V and 48 V vehicles in mind, this update is equally useful for stationary storage systems, solar arrays, and light EVs. Anywhere accurate current measurement and thermal feedback matter, the new MLX91230 and MLX91231 can help keep systems safe and stable.

By folding external NTC sensing into an already capable IVT platform, Melexis is giving engineers a practical way to improve thermal awareness and reliability without adding more hardware.

Learn more and read the original article on www.melexis.com