Melexis has introduced a new automotive-grade variant of the MLX90382 magnetic encoder, designed to support the industry’s continued move toward fully electronic and x-by-wire motor control. As steering, braking and suspension systems become more dependent on digital feedback loops, the need for encoders that combine accuracy, speed and resilience has grown sharply. The MLX90382 addresses this shift with high resolution, zero-latency signal processing and strong immunity to stray magnetic fields, making it suitable for demanding E-chassis environments.

Melexis has introduced a new automotive-grade variant of the MLX90382 magnetic encoder, designed to support the industry’s continued move toward fully electronic and x-by-wire motor control. As steering, braking and suspension systems become more dependent on digital feedback loops, the need for encoders that combine accuracy, speed and resilience has grown sharply. The MLX90382 addresses this shift with high resolution, zero-latency signal processing and strong immunity to stray magnetic fields, making it suitable for demanding E-chassis environments.

High-Resolution Magnetic Sensing With Zero Latency

The device combines a Hall-based magnetic front end with an analogue-to-digital converter and on-chip digital signal processing. This architecture supports up to 16-bit resolution and maintains zero-latency behaviour, which is important for systems where control loops depend on highly predictable timing. Melexis applies its latest Triaxis technology to measure all three magnetic flux components. In addition, the IC evaluates the differential Z-axis field to determine absolute angle position and rotational speed. With operation up to 200,000 electrical rpm and tolerance to stray fields up to 4 kA per metre, the MLX90382 is built for applications where thermal stress, vibration and electromagnetic interference are standard conditions, especially within electric vehicles.

Versatile Mounting Options and Multiple Output Interfaces

The encoder supports both on-axis and off-axis placement, which gives design teams freedom when routing wiring looms or accommodating through-shaft mechanical layouts. This is particularly helpful in hollow-shaft applications used in modern steering and braking systems. Interface support includes ABI, UVW, PWM, SPI and SSI outputs. This range of digital protocols provides compatibility with a broad set of existing automotive motor control architectures, helping reduce integration overhead for OEMs and Tier 1 suppliers.

Automotive Robustness and Functional Safety

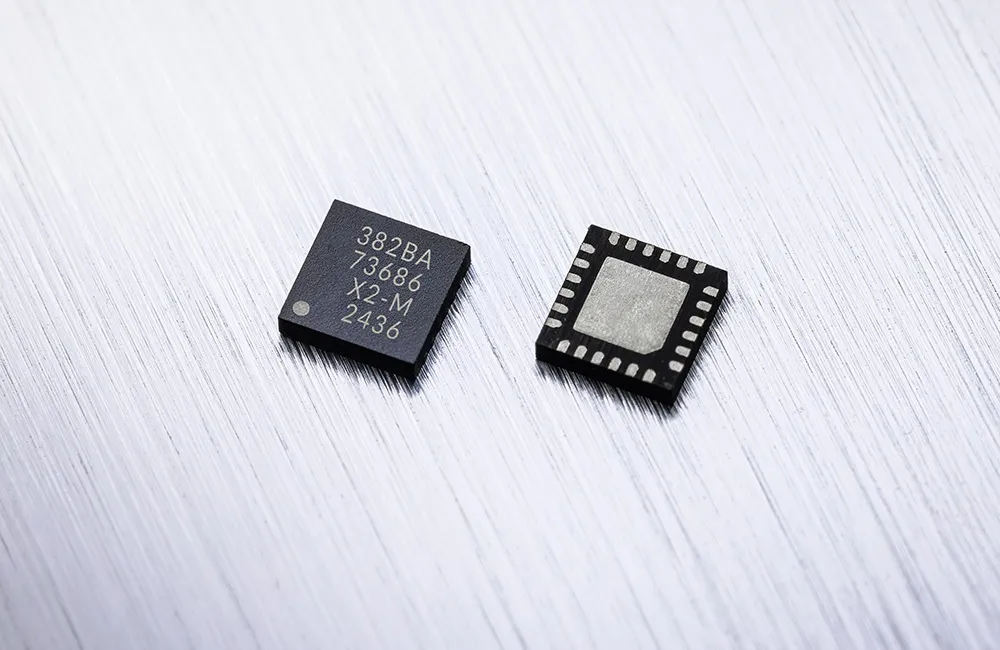

The MLX90382 meets AEC-Q100 Grade 0 requirements and operates from minus 40 degrees Celsius to 150 degrees Celsius. These ratings ensure reliable performance across the wide temperature swings expected within E-chassis assemblies. The device is offered in QFN24 single-die and TSSOP16 dual-die packages. The dual-die option supports ASIL D system integration, aligning with ISO 26262:2018 processes used in safety-critical control modules. As automotive functions migrate to fully digital actuation, encoders with built-in diagnostic coverage and predictable behaviour become essential for maintaining system availability and safety.

Industry Perspective

Melexis emphasises that the demand for precise, digital feedback continues to rise as manufacturers roll out steer-by-wire, brake-by-wire and active suspension platforms. The MLX90382 has been positioned to support this transition by pairing accurate magnetic measurement with robust digital communication and strong immunity to environmental disturbances. By offering designers a sensor capable of operating in these tougher conditions, Melexis aims to simplify the development of next-generation E-chassis systems while maintaining cost-effectiveness.

Learn more and read the original article on www.melexis.com