Illuminated tactile switches are a familiar part of electronic systems, but they have always brought one awkward limitation. Most are not suited to reflow soldering. That means extra steps in production, sleeves to protect plastics, or wave soldering passes that break the rhythm of a modern SMT line.

Illuminated tactile switches are a familiar part of electronic systems, but they have always brought one awkward limitation. Most are not suited to reflow soldering. That means extra steps in production, sleeves to protect plastics, or wave soldering passes that break the rhythm of a modern SMT line.

As assembly processes shift almost entirely to reflow, this gap has become more noticeable. Littelfuse’s new K5V4 switches are designed to address it directly. Using a high-temperature polyarylate rated to 250 °C, they survive reflow without special handling. For manufacturers, that change alone removes one of the persistent bottlenecks in switch integration.

A Look at the K5V4

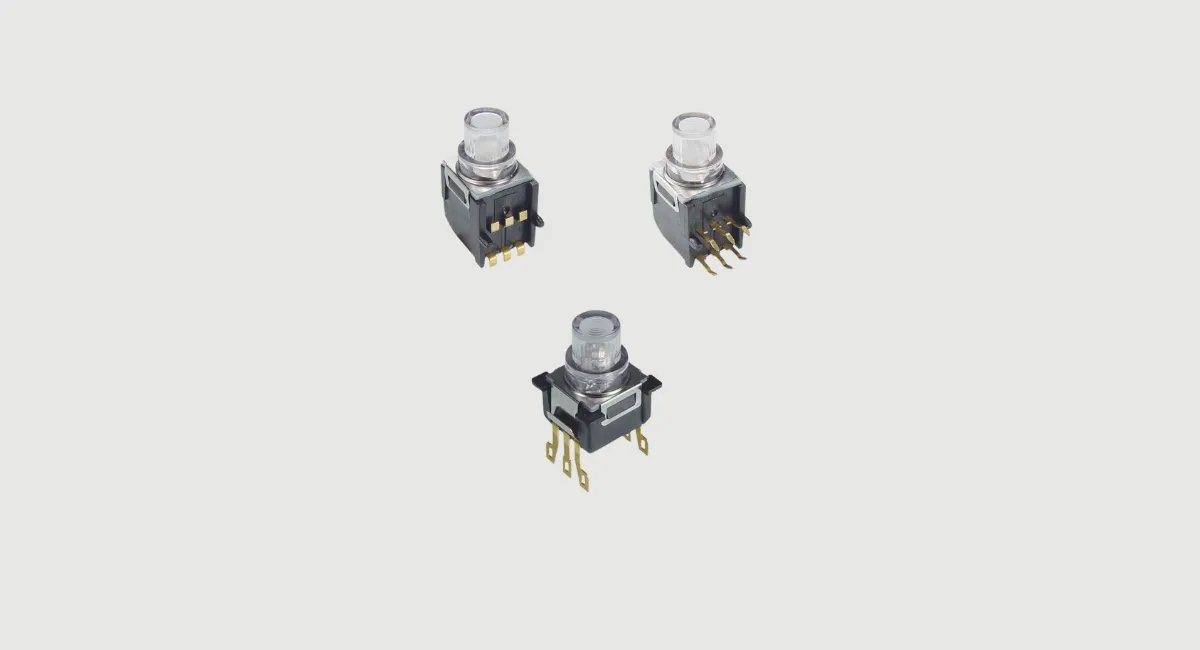

The K5V4 is the latest addition to the K5V family, offered in Gull Wing and Pin-in-Paste options. Despite a small footprint, the switches keep the long travel that defines the series. They feel crisp to press, with a 4 N actuation force and an audible click that makes them hard to miss in use.

Illumination is built in, with LEDs available in several colours including bi-colour versions. The mechanism is housed in a compact dust-resistant shell, while gold-plated domes handle the contacts, improving long-term reliability where frequent actuation is expected.

Where They Fit Best

These switches are aimed at places where user feedback and manufacturability are equally important. Data centres and networking gear need clear, reliable buttons for resets and diagnostics. Industrial panels benefit from long-travel switches that resist accidental activation. Professional audio and video systems gain from the illuminated options when working in dark environments.

For engineers, the advantage is having a switch that behaves the way users expect while still fitting into reflow lines. No extra sleeves, no wave soldering. Just another component in the SMT process.

Why It Matters

Competing designs often stop short of reflow compatibility, leaving OEMs with workarounds. Littelfuse is positioning the K5V4 as a straightforward alternative: a tactile switch with the right feel, illumination for feedback, and materials tough enough for high-temperature soldering.

In practice, that means reduced assembly cost, simpler workflows, and fewer compromises between ergonomics and production efficiency. It is a small change in one component, but one that removes a recurring friction point in dense system design.

Learn more and read the original article on www.littelfuse.com