Industrial electronics often place fast digital interfaces right beside high power switching components. That mix creates noise, ground shifts and transients that can distort signals long before they reach a controller. Isolation prevents fault propagation, but the isolators themselves must keep up with rising data rates in automation and factory networking. When delays grow or edges distort, motion control loops can lose bandwidth and measurement accuracy falls off.

Industrial electronics often place fast digital interfaces right beside high power switching components. That mix creates noise, ground shifts and transients that can distort signals long before they reach a controller. Isolation prevents fault propagation, but the isolators themselves must keep up with rising data rates in automation and factory networking. When delays grow or edges distort, motion control loops can lose bandwidth and measurement accuracy falls off.

What the Product Does

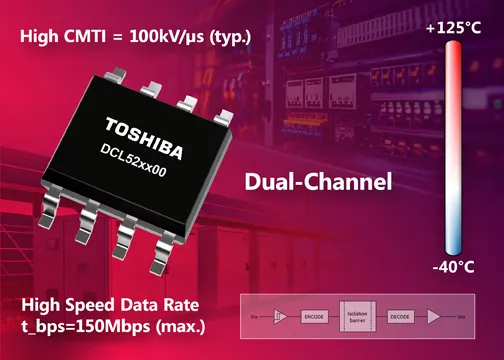

Toshiba is adding more choice to its digital isolator lineup with a new set of dual channel devices known as the DCL52xx00 series. They are designed to move data quickly between isolated domains while keeping signal shape intact, so control decisions reflect the actual state of the system. Rather than trying to push analogue optocouplers harder, Toshiba uses a magnetic coupling method that supports higher speeds and improves noise tolerance.

Key Technical Details

Each isolator in the series supports up to 150 megabits per second, which is useful for interfaces such as isolated UARTs or parallel data structures running close to power devices. The parts achieve a typical common mode transient immunity of 100 kilovolts per microsecond, so they can ride through large voltage events without misinterpreting data. Pulse width distortion of 0.8 nanoseconds means a driver’s intended timing is still recognisable on the receiving side.

The channel configurations of the DCL520C00 and DCL520D00 are two forward channels, while the DCL521C00 and DCL521D00 pair one forward with one reverse channel, giving engineers direction flexibility depending on whether acknowledgements or control returns are needed across the isolation barrier.

These four variants expand Toshiba’s options for designers who need to match the direction and bandwidth of control signals without over-sizing components or adding extra isolation devices. And for systems that require more data paths, Toshiba’s existing quad channel lineup can be dropped into the same design approach.

Integration and Design Considerations

Real world industrial layouts rarely give signals the clean paths they want. These devices are built to block big transient swings and maintain logic levels even when grounds shift due to motor currents or power conversion. Short propagation delays help retain control loop responsiveness, which becomes increasingly important as plants drive towards finer positioning and more real time feedback.

Design teams already working with Toshiba isolators can keep familiar package sizes and protection schemes. Automotive qualified options exist elsewhere in the portfolio for equipment that crosses into EV charging or vehicle control, and Toshiba has signalled that more channel configurations are on the way.

Why It Matters

When digital isolation becomes a bottleneck, the automation system above it inherits that limitation. By expanding configuration options without changing the behaviour engineers rely on, Toshiba gives designers a bit more freedom to optimise their architecture rather than work around isolation overhead. Better timing, lower distortion and strong immunity help keep industrial communication stable even when the environment is anything but.

Learn more and read the original announcement on www.toshiba.semicon-storage.com