Silicon carbide power modules are pushing switching speeds higher each year, which brings clear efficiency gains but also raises the risk of voltage overshoot, ringing, and thermal hotspots. These behaviours often stem from parasitic elements that are difficult to eliminate in real layouts. Melexis’ MLX91299 approaches this problem by integrating a silicon-based RC snubber directly inside the module, giving engineers a controlled way to manage fast transients without relying on bulky external components.

Silicon carbide power modules are pushing switching speeds higher each year, which brings clear efficiency gains but also raises the risk of voltage overshoot, ringing, and thermal hotspots. These behaviours often stem from parasitic elements that are difficult to eliminate in real layouts. Melexis’ MLX91299 approaches this problem by integrating a silicon-based RC snubber directly inside the module, giving engineers a controlled way to manage fast transients without relying on bulky external components.

Managing Fast Switching in Wide Bandgap Designs

As SiC devices transition from early adoption to mainstream automotive and industrial platforms, designers are discovering that managing transient behaviour is just as important as choosing the right MOSFET. High-frequency oscillations can generate leakage currents, stress the die, and reduce long-term reliability. Melexis reports that early measurements show switching losses dropping by as much as half when the integrated snubber is added. That scale of reduction affects system-level decisions such as allowable switching frequency, cooling strategy, or the size of magnetics in high power converters.

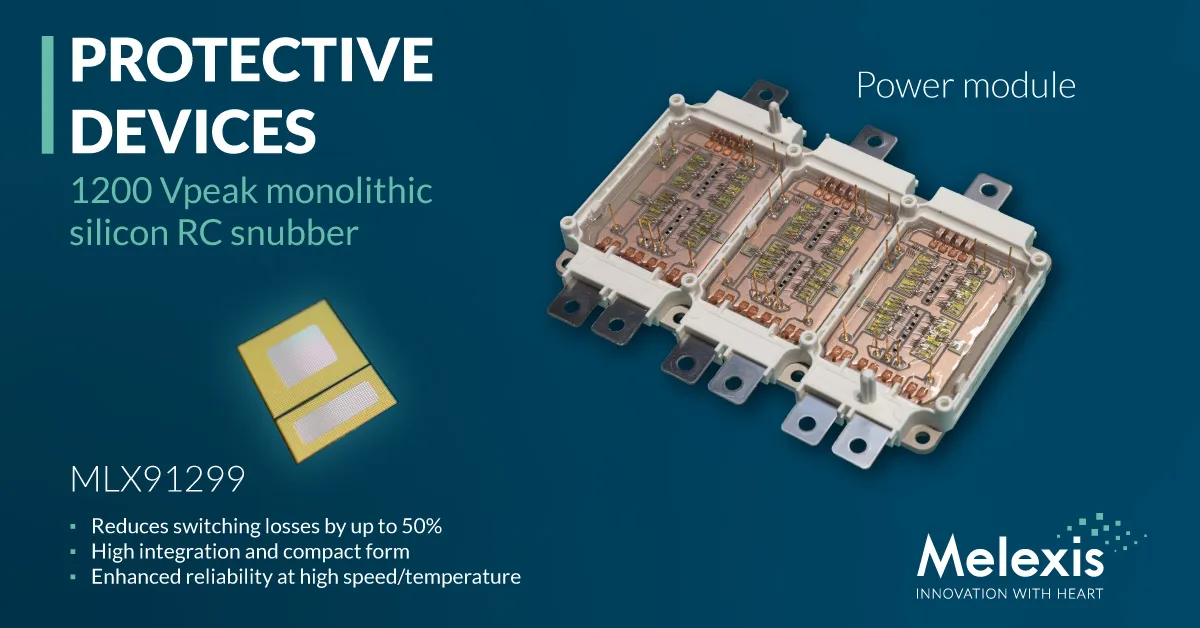

Integrated Structure and Electrical Performance

The MLX91299 pairs a resistor and capacitor on a single silicon substrate engineered for high-voltage environments. Its breakdown rating above 1500 V makes it suitable for traction inverters, DC fast chargers, onboard chargers, and other platforms where voltage headroom is essential. Unlike discrete snubbers mounted on a PCB, the device uses backside metallization compatible with sintering and solder attachment. This allows the snubber to sit next to SiC switches and share the same thermal path, which avoids localised heating and keeps module behaviour predictable even at junction temperatures reaching 200 degrees Celsius.

Assembly Practicalities and System-Level Advantages

Snubber design is often dictated by layout. Off-board components can introduce parasitic inductances that defeat the purpose of the snubber in the first place. By integrating the MLX91299 within the power module, engineers have far tighter control over loop area, energy absorption, and EMC performance. The compact silicon form factor fits into existing module footprints, reducing assembly complexity and keeping high-frequency behaviour consistent across devices. For automotive teams working toward higher switching speeds or more compact inverter housings, this controlled integration is a practical advantage.

Shaping the Next Generation of High-Voltage Modules

As power modules evolve toward higher power density, smaller footprints, and higher thermal limits, the need for built-in protective elements will continue to grow. The MLX91299 is the first member of the Melexis protective device family, signalling a broader move toward embedding support functions directly within the stack. For engineers, this trend means fewer external components, more predictable switching, and the ability to push SiC devices harder while keeping reliability under control. It also sets the stage for future modules where sensing, protection, and switching elements coexist more tightly than they do today.

Learn more and read the original announcement at www.melexis.com