The move toward 6G is pushing RF hardware into regions where materials start to constrain performance more than the circuits themselves. Operating in the FR3 band means antennas, filters and front end modules need substrates that can stay extremely low loss while remaining thin enough for compact devices. Murata’s new ULTICIRC LCP flexible substrate is built around that problem. By embedding an Inner Cavity structure inside the material, the dielectric constant drops below 2.0, allowing high frequency signals to travel with less attenuation even as the substrate gets thinner.

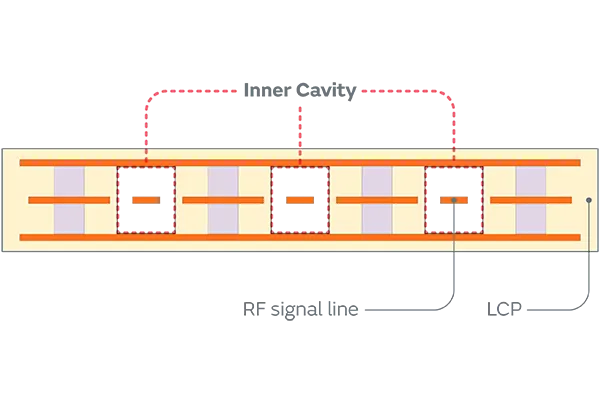

The move toward 6G is pushing RF hardware into regions where materials start to constrain performance more than the circuits themselves. Operating in the FR3 band means antennas, filters and front end modules need substrates that can stay extremely low loss while remaining thin enough for compact devices. Murata’s new ULTICIRC LCP flexible substrate is built around that problem. By embedding an Inner Cavity structure inside the material, the dielectric constant drops below 2.0, allowing high frequency signals to travel with less attenuation even as the substrate gets thinner.

Lower Dielectric Constant For High Frequency Operation

Every generation of wireless technology has pushed dielectric materials harder, but the FR3 band sharpens the challenge because traditional thinning of flexible substrates increases loss. Murata addresses this by carving an internal cavity into the LCP structure, reducing the effective permittivity without compromising mechanical stability. A Dk below 2.0 significantly improves signal propagation at tens of gigahertz, which is where antenna arrays and beamforming modules will operate in early 6G designs. The improvement is not only about loss but also consistent phase behaviour, which becomes critical when many radiating elements must remain aligned across wide bandwidths.

Image Credit: Murata

Image Credit: Murata

Structural Design Built For Miniaturised RF Modules

LCP has been popular in RF packaging because of its moisture resistance, dimensional stability and relatively low dielectric properties. ULTICIRC builds on those traits with an adhesive free lamination method that avoids adding layers which could introduce unwanted dielectric variation. The Inner Cavity works within that structure without creating spring back, which helps keep multilayer assemblies flat during reflow or mechanical bending. Engineers designing smartphones, wearables or compact communication modules need this level of predictability when routing antenna feeds or integrating high frequency interconnects into curved surfaces.

Integration Considerations For FR3 Hardware

Designing for FR3 requires more than shifting antenna geometries upward in frequency. It demands substrates that minimise dispersion, resist humidity driven drift and maintain stable performance across temperature cycles. ULTICIRC’s combination of low Dk and LCP barrier properties helps address these constraints, especially for modules that sit close to the chassis where condensation or environmental exposure can degrade RF characteristics over time. In practice, this substrate allows engineers to thin down stackups while preserving low loss behaviour, which helps reduce overall module size and leaves more freedom for routing control lines, power planes or matching networks.

Preparing For Next Generation Wireless Systems

The early stages of 6G development show a clear trend toward distributed antenna arrays and dense RF front ends built into compact enclosures. Material science therefore becomes a primary driver of system level performance. ULTICIRC points to how substrates may evolve as FR3 deployment grows, highlighting the need to decouple mechanical thinness from dielectric penalty. For engineers planning long term platform updates, this kind of material innovation offers a path toward higher frequency operation without heavy redesign of module geometry. As commercial interest in FR3 accelerates, substrates like ULTICIRC will likely influence how OEMs build and standardise their RF stacks.

Learn more and read the original announcement at www.murata.com