Automotive electronics rarely fail because a design cannot meet a headline specification. More often, the problem is heat. Switching and control stages sit close to loads, run continuously, and operate in environments where airflow is limited and ambient temperatures are high. In those conditions, even modest conduction losses add up quickly. That is the gap Diodes Incorporated is targeting with its DXTN/P 78Q and 80Q series, a set of ultra low VCE(sat) NPN and PNP bipolar transistors designed to make high current automotive circuits more thermally manageable without forcing a move to more complex solutions.

Automotive electronics rarely fail because a design cannot meet a headline specification. More often, the problem is heat. Switching and control stages sit close to loads, run continuously, and operate in environments where airflow is limited and ambient temperatures are high. In those conditions, even modest conduction losses add up quickly. That is the gap Diodes Incorporated is targeting with its DXTN/P 78Q and 80Q series, a set of ultra low VCE(sat) NPN and PNP bipolar transistors designed to make high current automotive circuits more thermally manageable without forcing a move to more complex solutions.

Lower Saturation Voltage Where It Actually Counts

In many automotive designs, bipolar transistors are still the sensible choice for driving MOSFETs and IGBTs, switching loads, or controlling solenoids and relays. The challenge is that these devices often operate in saturation for long periods, so VCE(sat) directly determines how much power is wasted as heat. The DXTN/P 78Q and 80Q devices push that loss down to unusually low levels, with saturation voltages around 17 mV at 1 A. In practice, that can halve conduction losses compared to older devices in the same role. This matters because it gives engineers back thermal margin, either to increase current capability or to shrink copper and heatsinking without compromising reliability.

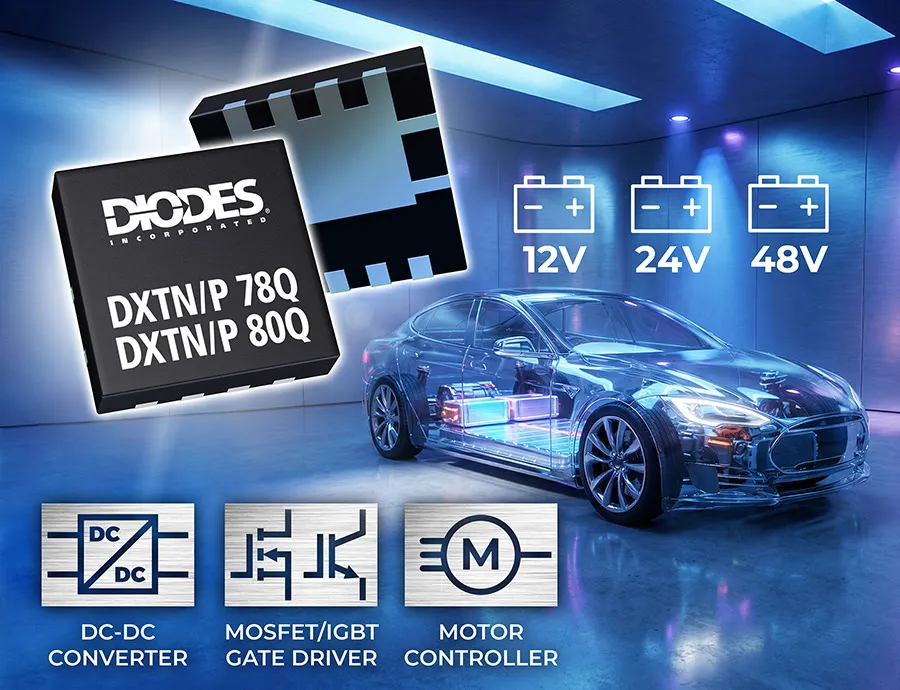

Electrical Headroom for 12 V, 24 V, and 48 V Systems

Modern vehicles rarely rely on a single supply rail. Body electronics, auxiliaries, and emerging electrified subsystems all coexist, often within the same module. Diodes has covered that spread by offering breakdown voltage ratings from 30 V to 100 V across the DXTN/P 78Q and 80Q families. The higher current DXTN/P 80Q variants are rated for up to 10 A continuous operation with pulse capability reaching 20 A, which makes them suitable for demanding switching tasks rather than just signal-level control. Low on-state resistance down to 12 mΩ complements the low VCE(sat), keeping power dissipation predictable even as current rises.

PowerDI 3333 Packaging and Thermal Behaviour

Package choice often decides whether a device can be used at all in dense automotive layouts. These transistors are housed in Diodes PowerDI 3333-8 package, measuring just 3.3 mm by 3.3 mm. Compared with older SOT223 packages, that footprint reduction can be dramatic, freeing space for additional circuitry or allowing a tighter module outline. The underside heatsink is not just a convenience feature. With a junction-to-lead thermal resistance of 4.2°C/W, it provides a realistic path for moving heat into the PCB. Sidewall plateable features improve automated optical inspection and solder joint integrity, which is a practical advantage in high volume automotive manufacturing where inspection time and yield matter.

Reliability Expectations in Harsh Environments

Automotive qualification is not only about electrical limits. These devices are rated for continuous operation up to +175°C junction temperature and offer strong ESD protection with 4 kV HBM and 1 kV CDM ratings. For engineers, that translates into fewer external protection compromises and more confidence when placing devices close to connectors or exposed loads. Standard versions of the same devices are also available for industrial and commercial designs, which simplifies reuse across product families.

Incremental Gains That Enable Denser Electronics

Interestingly, the DXTN/P 78Q and 80Q series highlight a broader trend. Rather than replacing established architectures, manufacturers are refining them. By extracting lower losses, better thermal behaviour, and more usable packaging from bipolar transistors, designers can continue to rely on a familiar device class while meeting tighter efficiency and space targets. For engineers, the takeaway is simple. Small improvements at the component level can unlock meaningful system-level benefits, especially in environments where every degree and every square millimetre counts.

Learn more and read the original announcement at www.diodes.com