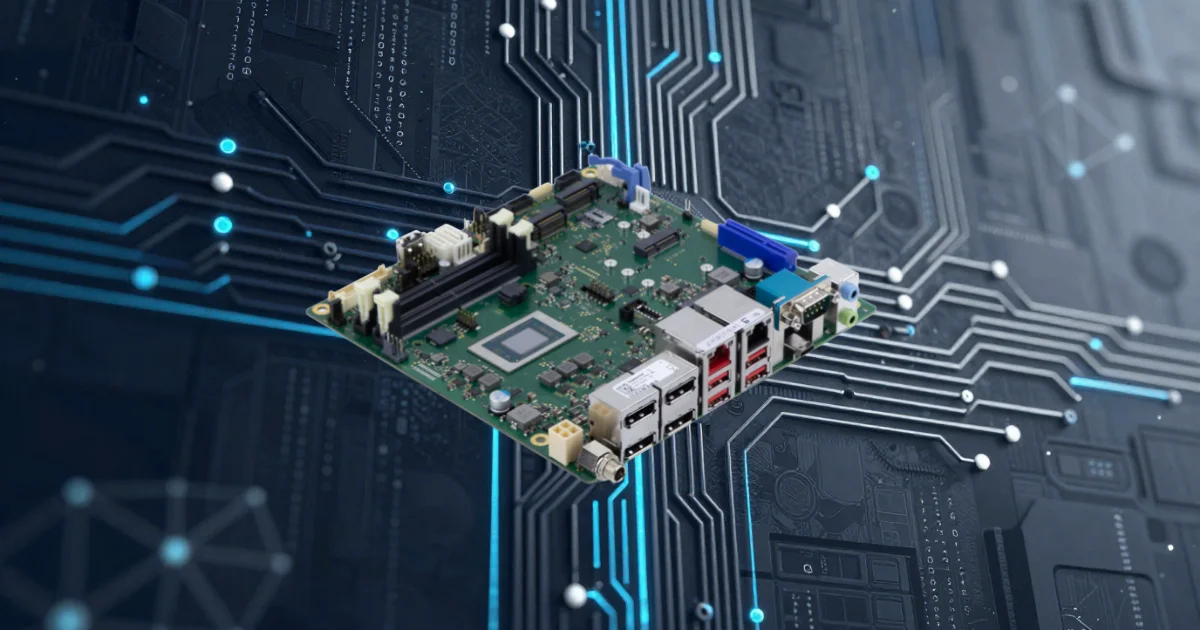

Edge systems that run vision workloads and deterministic control on the same hardware often reach a point where CPU load, graphics processing and sensor input begin to collide. When that happens, timing drift, dropped frames or thermal throttling tend to surface long before the application grows in complexity. The K4131 Px motherboard from Kontron approaches this constraint by using the Ryzen AI Embedded P100 series from AMD to separate high level tasks, graphics pipelines and AI inference without stretching the power envelope of a compact mITX design.

Edge systems that run vision workloads and deterministic control on the same hardware often reach a point where CPU load, graphics processing and sensor input begin to collide. When that happens, timing drift, dropped frames or thermal throttling tend to surface long before the application grows in complexity. The K4131 Px motherboard from Kontron approaches this constraint by using the Ryzen AI Embedded P100 series from AMD to separate high level tasks, graphics pipelines and AI inference without stretching the power envelope of a compact mITX design.

Compute Architecture Built For Parallel Edge Workloads

One detail that stands out in this platform is how the compute domains are organized. The P100 processors combine multi core CPU compute with an integrated AI engine, which allows inference to run alongside graphics and control logic without pushing everything through the same cores. In real industrial systems this reduces the jitter that usually appears when machine vision, HMI rendering and sensor polling fight for scheduling. It also shortens decision loops in applications where latency matters, such as robotic cells or inspection stations that react to changing inputs every few milliseconds.

Graphics And Display Paths Suited For Multi-Screen HMI Designs

The display configuration provides several routes for building operator interfaces or multi camera dashboards. Up to four DisplayPort connections, together with LVDS and embedded DisplayPort, give designers flexibility when mixing modern panels with established industrial displays. This becomes important in factories where equipment upgrades happen gradually and HMIs must integrate with existing enclosures. A small detail worth noting is that embedded display paths reduce the need for additional adapters, which helps keep thermal load and board complexity predictable in panel mount systems.

Expansion Options That Support Modular Industrial Builds

Many edge units evolve as requirements change, and the K4131 Px supports this with up to four M.2 slots that can host storage, wireless modules or add on accelerators. For integrators who need 5G, Wi Fi or additional storage for vision datasets, having multiple high speed slots on a compact board reduces the need for carrier expansions. Legacy connectivity is addressed through multiple COM ports that allow direct integration with field devices, PLCs and industrial sensors that still rely on serial communication. In many factories old and new equipment end up side by side, and the extra serial ports make it easier to keep those systems talking without redesigning the whole setup.

Power Handling And Mechanical Traits For Industrial Environments

Supply rails in industrial cabinets are rarely clean, and voltage can wander when multiple loads kick in. The 9 to 34 V range gives the board enough room to keep running without complaining about those swings. Mechanical integration is further supported by the availability of the SMARTCASE S740 enclosure, which provides a known thermal and mechanical profile for teams who want predictable performance without designing a full housing. This combination suits installations in machinery panels, inspection stations and compact compute nodes positioned close to production lines.

Applications That Benefit From Local AI And Multi Display Output

Systems that juggle several camera feeds or run operator displays tend to benefit first, because they push both graphics and inference at the same time. Doing that work locally usually trims the delay that appears when everything has to travel through a backend before a decision is made. Robotics and AMRs also gain from the combined graphics and AI handling, while industrial gateways use the board’s expansion slots and legacy interfaces to bridge older machinery with modern networks. For engineers, the takeaway is that the K4131 Px provides a compact route to combine AI inference, graphics rendering and deterministic control within a single mITX board while keeping thermal behavior and power input predictable.

Learn more and read the original announcement at www.kontron.com