SEPIC converters have been around for decades, but their flexibility keeps them relevant in modern designs. Able to step voltage up, down, or hold it steady, the topology fits neatly into applications where the input source isn’t predictable. Think battery-powered devices that drain unevenly, automotive systems that experience wide voltage swings, or LED drivers that demand stable output under changing conditions.

SEPIC converters have been around for decades, but their flexibility keeps them relevant in modern designs. Able to step voltage up, down, or hold it steady, the topology fits neatly into applications where the input source isn’t predictable. Think battery-powered devices that drain unevenly, automotive systems that experience wide voltage swings, or LED drivers that demand stable output under changing conditions.

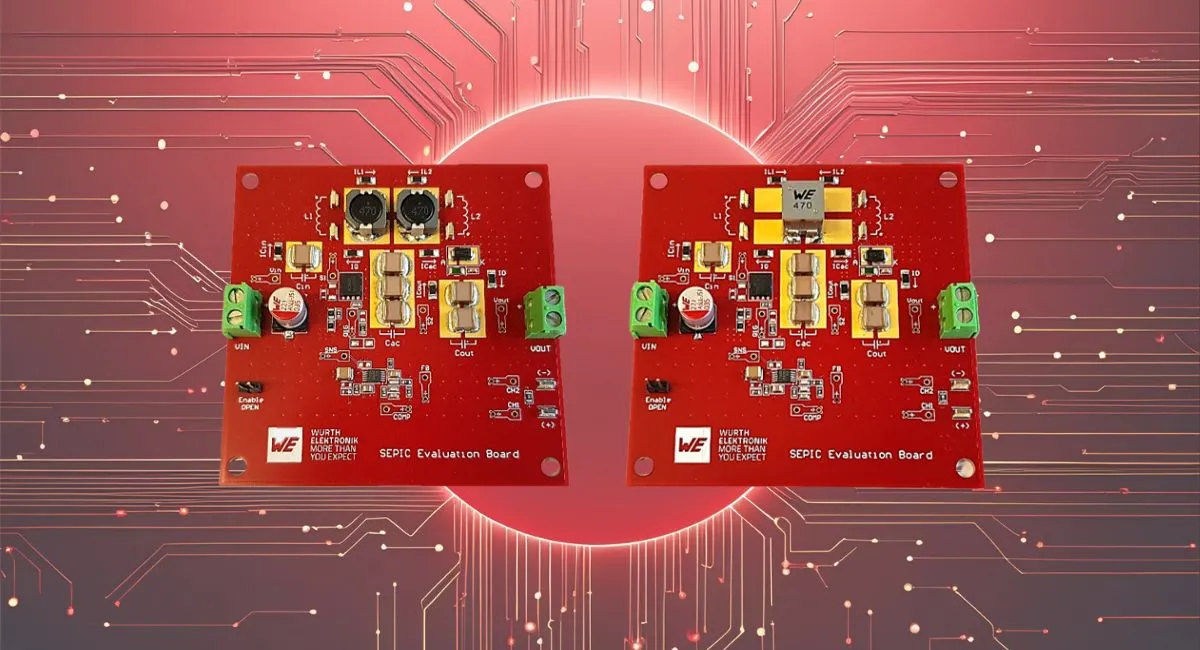

Würth Elektronik’s latest application note, ANP135, revisits the SEPIC with a detailed look at how it behaves in both continuous and discontinuous conduction modes. The focus is on the magnetic side of the design, with worked examples, SPICE simulations, and measurements taken from real prototypes.

The Role of Coupled Inductors

A SEPIC stage needs two inductors, and designers can either place them separately or wind them together on a common core. Würth’s note makes a strong case for the latter. Coupling the inductors trims the overall inductance requirement, reduces part count, and crucially, enables what the engineers call “ripple current steering.”

This steering effect shifts ripple from the input to the output winding, which helps suppress conducted EMI noise. It’s a useful trick for designs facing strict EMC limits. Interestingly, the note points out that leakage inductance, usually considered a weakness, can actually improve SEPIC performance when managed correctly.

“Understanding the coupling factor is critical,” explains Eleazar Falco, Senior Application Engineer at Würth Elektronik. “In contrast to other converter topologies, a higher leakage inductance may provide an advantage here”.

Practical Takeaways for Designers

Rather than presenting only theory, the guide walks through test data and simulated behaviour, giving engineers a realistic sense of how coupled versus uncoupled implementations compare. The message is clear: if space, efficiency, and EMI performance are priorities, a coupled inductor design is often the smarter choice.

For engineers working on automotive, lighting, or renewable energy systems, Würth Elektronik’s analysis offers practical direction on how to push SEPIC converters further while keeping designs robust and compliant.