Electromagnetic compatibility (EMC) remains one of the most persistent hurdles in electric drivetrain design. Inverter-generated noise can undermine both emissions compliance and immunity performance, making it difficult for manufacturers to meet automotive standards on time. For mid-sized OEMs and system integrators, developing bespoke filter solutions often adds significant cost and delays to vehicle programmes.

Electromagnetic compatibility (EMC) remains one of the most persistent hurdles in electric drivetrain design. Inverter-generated noise can undermine both emissions compliance and immunity performance, making it difficult for manufacturers to meet automotive standards on time. For mid-sized OEMs and system integrators, developing bespoke filter solutions often adds significant cost and delays to vehicle programmes.

Standardised Filter Platform

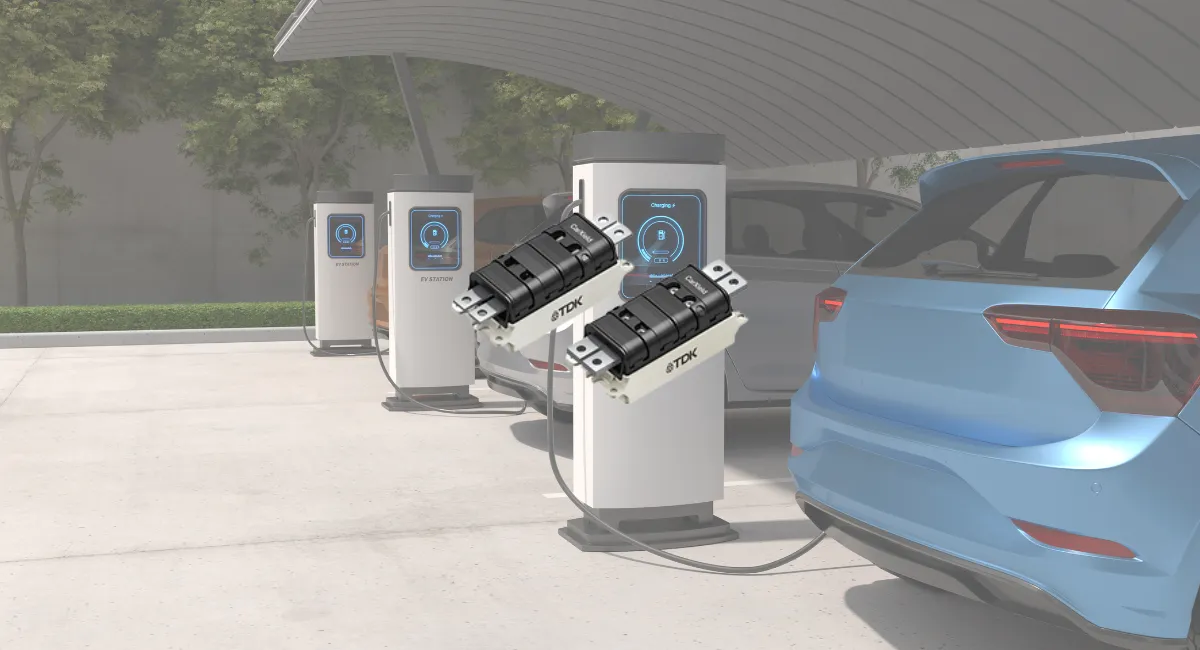

TDK has introduced CarXield, a standardised series of EMC filters (ordering code B84252x) for xEV inverters rated at 500 V and 1000 V. By offering validated, compact EMI solutions off the shelf, CarXield is intended to shorten development cycles and accelerate market entry for e-mobility manufacturers.

The filters suppress inverter noise on battery lines, improving overall EMC behaviour and easing regulatory approval. Each unit measures 140 × 59 × 50 mm, with rated currents up to 400 A at +85 °C and transient peaks up to 1000 A. Typical DC resistance is only 0.1 mΩ, helping to minimise conduction losses in high-current paths.

Core Technology and Construction

CarXield filters use nanocrystalline core material, which combines high permeability with low losses, making it effective at attenuating high-frequency interference in demanding inverter environments. Integrated X2 or Y2 class capacitors, together with passive discharge functionality, support both safety and long-term reliability.

To aid integration, the filters are available with or without copper busbars and can be supplied with passivated finishes. These options provide flexibility for different thermal and spatial requirements, allowing engineers to incorporate the modules without extensive redesign.

Automotive Validation

The series is certified to AEC-Q200 and validated against MBN LV 124 profiles, ensuring compliance with automotive reliability and endurance standards. This level of validation enables faster system qualification and reduces the need for extended in-house testing.

Implications for xEV Design

For engineers, the benefit of a standardised EMC filter is a reduction in both design risk and development time. Rather than creating bespoke solutions for each platform, validated modules can be applied with predictable results. This can simplify compliance, cut engineering workload, and provide greater confidence in system robustness.

By combining high electrical performance with integration flexibility, TDK’s CarXield family offers a practical platform approach that may help accelerate the adoption of higher-voltage xEV architectures.

Learn more and read the original article on www.tdk.com