AI servers, high-speed networking, and industrial automation are all driving power demands higher than ever. Designers now face the challenge of moving from 48 V distribution rails to 12 V board-level supplies without burning through efficiency budgets. Even a small percentage loss at this stage generates significant heat, and in dense racks or compact industrial enclosures, heat quickly becomes the limiting factor.

AI servers, high-speed networking, and industrial automation are all driving power demands higher than ever. Designers now face the challenge of moving from 48 V distribution rails to 12 V board-level supplies without burning through efficiency budgets. Even a small percentage loss at this stage generates significant heat, and in dense racks or compact industrial enclosures, heat quickly becomes the limiting factor.

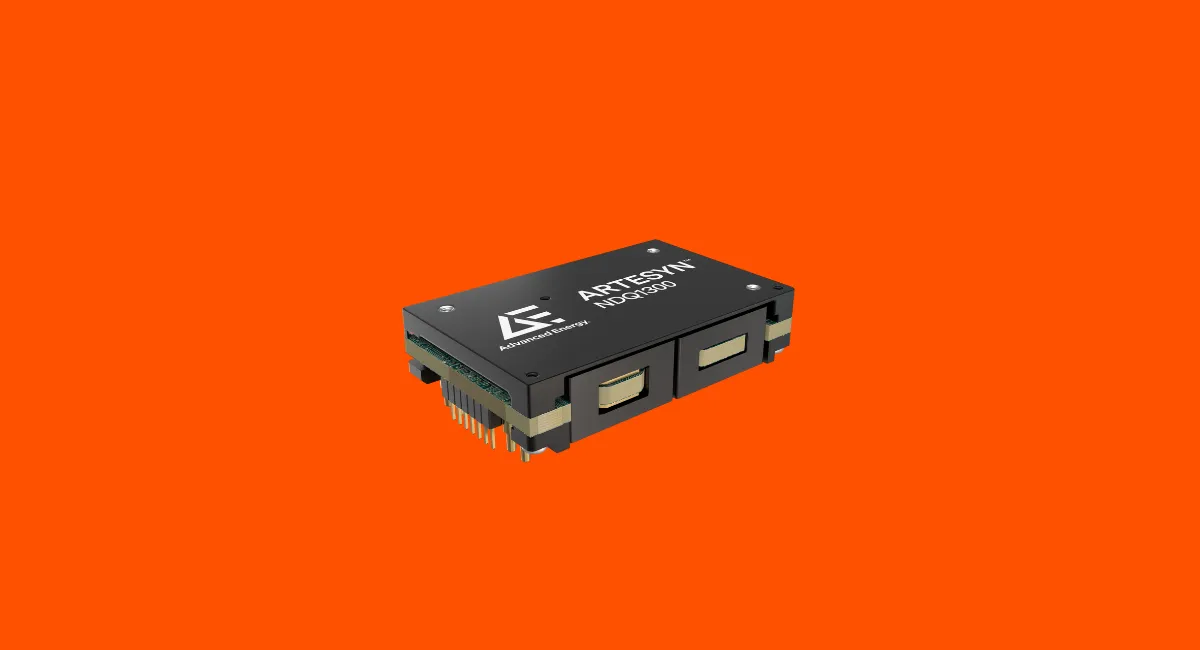

That’s the backdrop for Advanced Energy’s latest additions to its Artesyn bus converter line. The NDQ1300 and NDQ1600 are quarter-brick modules rated at 1300 W and 1600 W. Both take a 48 V input and provide a fully regulated 12 V output, with efficiencies reaching 98%.

Why a Flat Efficiency Curve Helps

Plenty of converters quote a high peak efficiency. What’s more unusual is maintaining that efficiency across the load range. The NDQ family does just that.

In practice, this means an AI server doesn’t see efficiency nosedive when shifting from idle to full workload. Instead, losses stay predictable, which makes thermal planning far easier. For engineers, the outcome is lower cooling overhead and more headroom for performance.

The use of a quarter-brick footprint also matters. It lets system designers increase available power without changing the overall board layout. For companies building platforms that scale from mid-range to high-end, this saves redesign effort and speeds up product rollouts.

Smarter Control with Digital Interfaces

Raw efficiency is only part of the story. The NDQ1300 and NDQ1600 include a PMBus digital interface, giving engineers real-time visibility of voltage, current, and temperature. That data can feed predictive maintenance tools or allow firmware-based adjustments, supporting smarter, more adaptive systems.

The modules also support current sharing and remote sensing. Multiple converters can be paralleled to scale output or provide redundancy. In data centres and industrial automation, that redundancy is often critical to avoid downtime.

Handling the Realities of Startup and Transients

Transient loads and inrush current at startup are familiar headaches in high-power designs. Both NDQ converters use a transformer-based topology that smooths these events. Systems come online more predictably, and downstream circuits are less exposed to stress.

For robotics or test equipment, where current draw can swing suddenly, this kind of resilience directly improves reliability.

Built for Thermal Headroom

Power density is only useful if it can be cooled. Advanced Energy has addressed this with a baseplate design that spreads heat efficiently and supports straightforward heatsink attachment. Rather than pushing thermal management onto the rest of the system, the modules provide their own path for continuous operation at full power.

Because they follow a standard quarter-brick format, the NDQ1300 and NDQ1600 also drop into existing designs. That compatibility means engineers can upgrade performance without a full re-layout, making it easier to support multiple product tiers from a shared platform.

The Bigger Picture

The NDQ1300 and NDQ1600 are not just higher-wattage entries in a product line. They reflect where power conversion is heading: higher efficiency sustained across real workloads, integrated digital control, and packaging that acknowledges thermal realities.

As AI, networking, and industrial systems continue to scale, converters like these act as more than simple building blocks. They become active enablers, allowing engineers to design platforms that balance density, efficiency, and reliability without constant compromise.

Learn more at www.advancedenergy.com