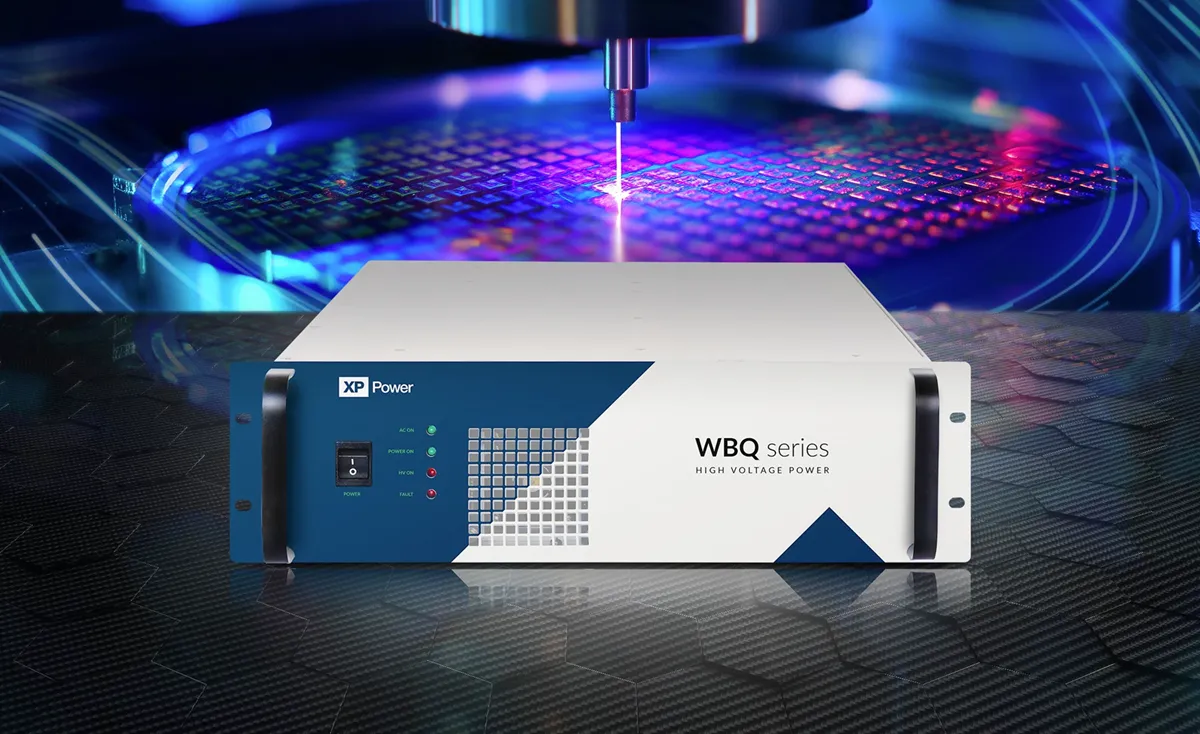

High voltage systems often grow bigger than engineers would like, especially when large ion sources, e beam tools or medical accelerators demand tens of kilowatts at tens of kilovolts. The hardware that feeds those loads can dominate a rack, leaving little room for the rest of the system. XP Power’s WBQ series steps into this space with a 10 kW supply that fits a 3U 19 inch envelope while offering output voltages as high as 100 kV. The aim is simple: reduce the physical footprint without giving up the stability, protection features or diagnostics that high voltage platforms rely on.

High voltage systems often grow bigger than engineers would like, especially when large ion sources, e beam tools or medical accelerators demand tens of kilowatts at tens of kilovolts. The hardware that feeds those loads can dominate a rack, leaving little room for the rest of the system. XP Power’s WBQ series steps into this space with a 10 kW supply that fits a 3U 19 inch envelope while offering output voltages as high as 100 kV. The aim is simple: reduce the physical footprint without giving up the stability, protection features or diagnostics that high voltage platforms rely on.

Why Size Reduction Matters In High Voltage Platforms

Semiconductor tools, additive manufacturing units and beam based systems often combine several high energy subsystems in a single rack. A smaller supply means more freedom to optimise layouts, add redundancy or incorporate additional control hardware without expanding the system’s physical boundary. The WBQ platform can also scale beyond 100 kW by paralleling units, which helps when powering larger ion implanters or high current processes that run continuously. By compressing 10 kW into a 3U space, XP Power gives designers more headroom to plan thermal paths and cable routing in dense environments.

Technical Behaviour That Shapes Performance

The supply offers regulated output voltages from 15 kV to 100 kV and uses a fully digital control loop. That digital architecture allows tighter control of load variations and gives engineers more flexibility to tune behaviour over the lifetime of the machine. Parameters such as arc control, arc quench and ramp rate are programmable, allowing the supply to react more intelligently to fault conditions or delicate transitions. Ripple sits at around 0.01 percent and line or load regulation is held to roughly 0.05 percent, figures that matter when powering precision systems where voltage drift translates directly to process variation. The use of SiC based switching stages helps push efficiency above 90 percent at full load, reducing heat build up and contributing to the air insulated design.

Diagnostics And Data Led Maintenance

High voltage systems demand robust protection and clear insight into operating behaviour. The WBQ platform integrates real time diagnostics, tracking input and output voltage, current and temperature. Datalogging supports long term monitoring and can help identify trends that point to component wear or drifting conditions. A black box reporting function adds another layer for event analysis by recording information around shutdown conditions, giving service teams a clearer view of root causes. These features support preventive maintenance strategies and reduce downtime in environments where the cost of an interruption can be significant.

Integration In Global And Multi Domain Systems

The supply accepts a standard 208 VAC three phase input, with an optional 400 VAC version for regions where that is the default. This makes the platform easier to integrate into global equipment without redesigning the entire input stage. Air insulation instead of oil reduces weight and simplifies handling, which is useful for field service and system upgrades. Combined with the ability to parallel units for higher power, the WBQ series fits into a wide span of high voltage applications from research installations to industrial processes where clean, stable and controllable high voltage rails are essential.

Learn more and read the original announcement at www.xppower.com